Ever wondered how a small rubber ring can prevent a high-pressure hydraulic system from leaking? That’s the power of an O-ring — compact yet crucial, simple yet essential.

At HENGOSEAL, we’ve been manufacturing and exporting industrial-grade O-rings to over 20 countries. Whether your application involves hydraulic cylinders, pneumatic equipment, or automotive engines, choosing the right O-ring can make or break performance.

What Is an O-Ring and How Does It Work?

An O-ring is a circular elastomer seal that blocks the passage of fluids or gases between mechanical parts. When compressed in a groove between two surfaces, it deforms to create a tight seal that resists pressure, temperature changes, and vibration.

In hydraulic systems, this deformation is the key to leak-free operation. You can learn more about their role in fluid power systems in our Hydraulic Seal Guide.

How to Select the Right O-Ring Material for Your Application?

Material selection impacts temperature resistance, chemical compatibility, and lifespan. Here’s a quick reference:

| Material | Temperature Range (°C) | Key Strengths | Common Applications |

|---|---|---|---|

| NBR (Nitrile) | -40 to 120 | Excellent oil resistance, cost-effective | Fuel systems, hydraulics |

| FKM (Viton®) | -20 to 230 | High temperature and chemical resistance | Aerospace, engines |

| EPDM | -50 to 150 | Weather, ozone, and steam resistance | Outdoor, HVAC |

| PTFE | -200 to 260 | Chemically inert, food-grade | Medical, food, laboratory |

If you’re unsure which to choose, see our detailed Silicone vs FKM O-Rings Comparison for complex environments.

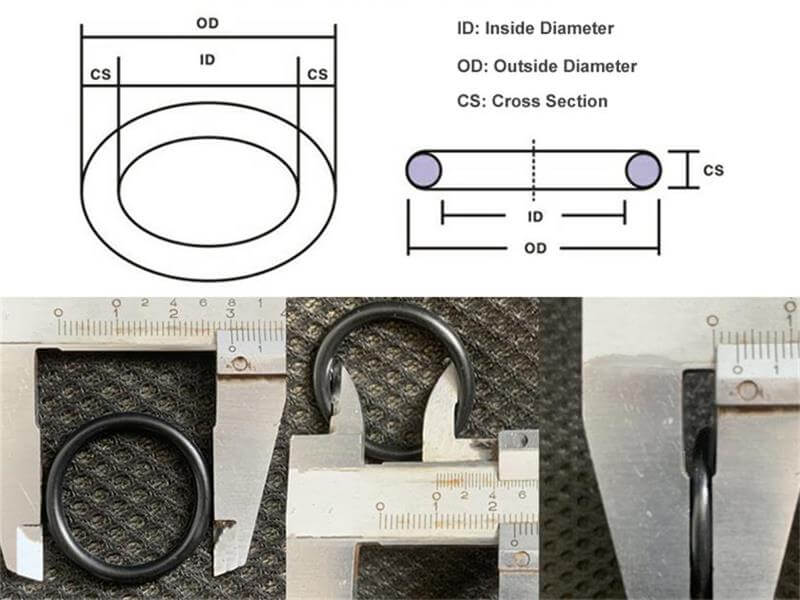

How Do You Measure O-Ring Sizes Correctly?

For the perfect fit, always measure:

- ID (Inner Diameter)

- OD (Outer Diameter)

- CS (Cross-section thickness)

Incorrect sizing leads to premature wear and leaks. Use our O-Ring Sizing Guide for step-by-step instructions.

Why Do O-Rings Fail and How Can You Prevent It?

Common causes of O-ring failure include:

- Wrong material choice for temperature or chemicals

- Over-compression or twisting during installation

- Exposure to incompatible fluids

- Reusing aged O-rings that lost elasticity

You can reduce downtime and replacement costs by following the preventive steps in our Seal Failure Prevention Guide.

Can O-Rings Handle Extreme Pressure and Temperature?

Yes, with the right compound.

For example, one manufacturer facing failures at 2500 PSI and 180°C switched to FKM O-Rings:

- Reduced leakage by 75%

- Extended service life by 5×

- Lowered maintenance costs by 40%

For multi-purpose stock, consider the O-Ring Assortment Kit to handle diverse applications.

How Much Do O-Rings Cost and What Affects Pricing?

Pricing depends on:

- Material type (NBR is economical, FKM/PTFE are premium)

- Size and tolerance

- Order quantity (bulk orders reduce cost per unit)

We explain pricing strategies in our O-Ring Cost & Selection Guide.

Where to Get Reliable O-Rings for Industrial Applications

If you need consistent performance and dependable supply:

- Browse our O-Ring Product Range including NBR, FKM, EPDM, and PTFE options

- Request technical drawings, OEM branding, and custom sizes

- Access our O-Ring Kit Guide to optimize your maintenance inventory

📧 [email protected] | 📱 WhatsApp: +86 17622979498

Related Topics You May Find Useful

- Hydraulic O-Rings: Types, Uses & Selection

- High-Pressure Hydraulic O-Rings: How to Choose the Most Durable Seals

- Buna-N vs EPDM O-Rings: Which One Should You Choose?

- EPDM vs FKM O-Rings: Which Material Is Right for Your Application?

- Prevent O-Ring Leakage Under High Pressure