Injection molding machines are the heart of modern plastics manufacturing—and their hydraulic systems demand precise, durable, and pressure-stable sealing.

Hydraulic seals for injection machines must handle high cycle frequencies, elevated oil temperatures, and tight tolerances. Choosing the wrong seal can lead to downtime, leakage, and costly maintenance.

In this guide, I’ll show you how to choose the best seal configuration for injection molding cylinders in 2025.

What challenges do seals face in injection molding machines?

Injection molding creates rapid, high-force movement during clamping and injection phases. Seals must survive:

- Continuous pressure cycling

- Oil temperatures up to 100–120°C

- Abrasion from fast strokes

- Tight groove tolerances with little room for extrusion

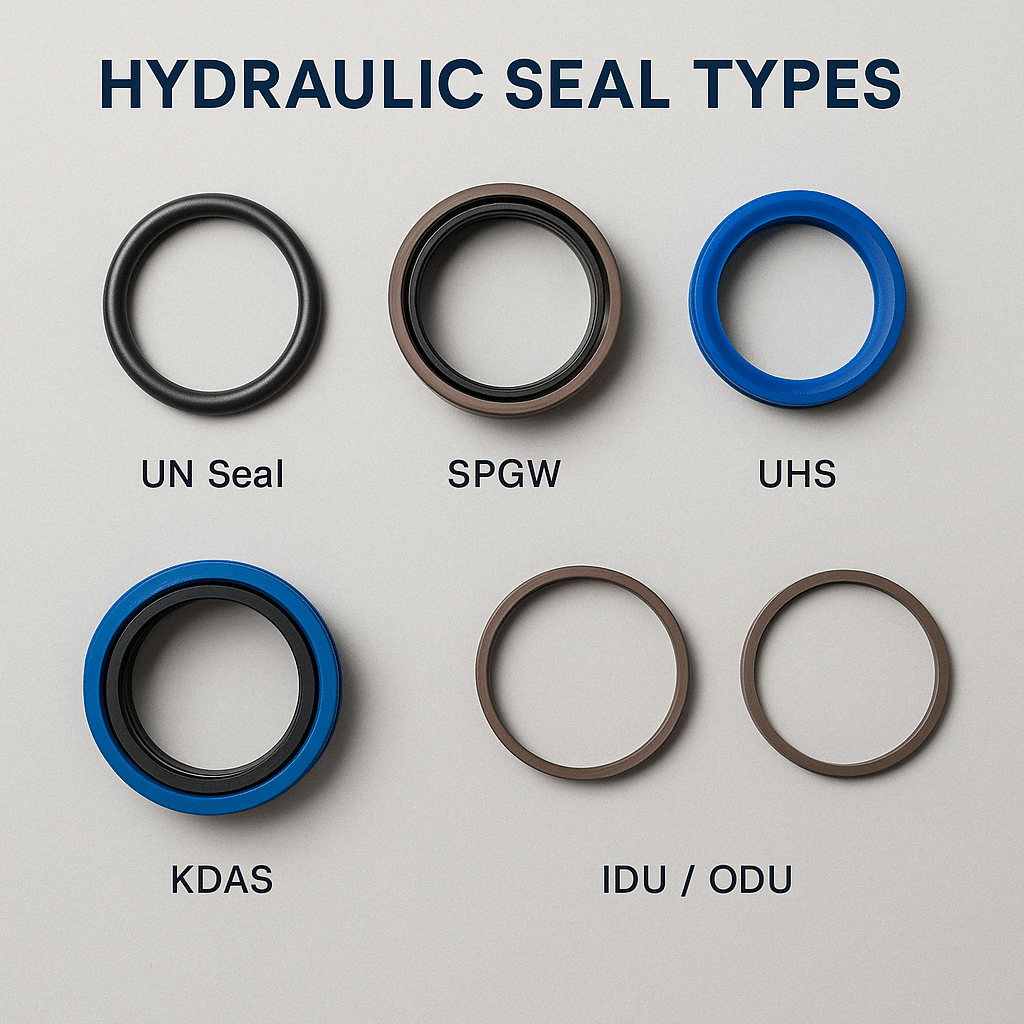

These systems also operate 24/7, making seal wear a critical factor. That’s why we recommend starting with high-end rod and buffer seals like our UN hydraulic seal และ KDAS buffer seal.

Which seal configuration works best for clamping cylinders?

Clamping cylinders generate the highest pressure in injection machines—often 30–40 MPa or more. You’ll need:

| ตำแหน่ง | ซีลที่แนะนำ | เหตุผล |

|---|---|---|

| ซีลก้าน | ตราประทับสหประชาชาติ | High-pressure, low-leakage design |

| ซีลบัฟเฟอร์ | ซีล KDAS | Prevents extrusion, handles pressure spikes |

| วงดนตรีไกด์ | PTFE Wear Ring | Keeps piston aligned under heavy load |

The KDAS’s multiple sealing lips act as both pressure breaker and scraper, protecting the UN seal from overloading. Learn more in our KDAS selection guide.

What seals work best for injection pistons?

Injection pistons move fast and require balanced sealing in both directions. A symmetrical seal is key.

✅ Use IDU or ODU piston seals—they handle bidirectional pressure and resist extrusion.

| กรณีการใช้งาน | Seal Option |

|---|---|

| Standard pressure | IDU Piston Seal |

| Higher speed/long stroke | ODU with tighter support rings |

If long stroke extrusion is a risk, upgrade to V-type hydraulic seals for improved sealing surface and material flexibility.

Which materials perform best under high heat and cycling?

Oil temperature in injection machines can exceed 100°C. In these cases, the following materials perform well:

| วัสดุ | ช่วงอุณหภูมิ | แอปพลิเคชั่นที่ดีที่สุด |

|---|---|---|

| ปู | -40°C ถึง 100°C | Buffer seals (shock) |

| เอฟเคเอ็ม | -20°C ถึง 200°C | Rod seals (chemical/oil) |

| พีทีเอฟ | -60°C to 260°C | Piston/wear rings (low friction) |

We often recommend a hybrid structure: FKM rod seal + PU buffer + PTFE piston guide for maximum durability. See similar recommendations in our Hydraulic Seal Stack Guide.

Can I use a seal kit for fast maintenance?

Yes. For injection machine rebuilds or preventive maintenance, we offer seal kits by cylinder size.

Each kit includes:

- ซีลก้าน

- Buffer ring

- ซีลลูกสูบ

- Wiper/dust seal

- Guide elements (if needed)

Custom kits are available even for low MOQ. If you're retrofitting or replacing OEM cylinders, see our custom hydraulic seal service.

บทสรุป

To keep injection molding machines running at peak efficiency, the right combination of rod, buffer, and piston seals is essential. Always match materials and pressure ratings to your system’s heat and cycle demands.

Request the best seals for your injection system

📩 mail:[email protected]

📞 WhatsApp:+86 17622979498

Related topic

- UN Hydraulic Seal: OEM Rod Sealing

- KDAS Buffer Seal Selection Guide

- IDU vs ODU Seal Comparison

- Hydraulic Seal Stack: How to Build It