Unexpected equipment downtime leads to production losses, increased maintenance costs, and customer dissatisfaction. Can selecting better seals really minimize these risks?

Choosing the correct seal type, material, and specifications plays a direct role in reducing machine downtime and improving operational reliability.

Seals are small components with significant impact. Their failure often results in fluid leakage, contamination, and premature part wear. Proper selection helps avoid these disruptions.

Why does incorrect seal selection cause equipment downtime?

Using the wrong seal type or material can lead to premature failure, leakage, or total system shutdown.

Mismatched materials, incorrect dimensions, or incompatible pressure ratings are among the most common causes of early seal failure.

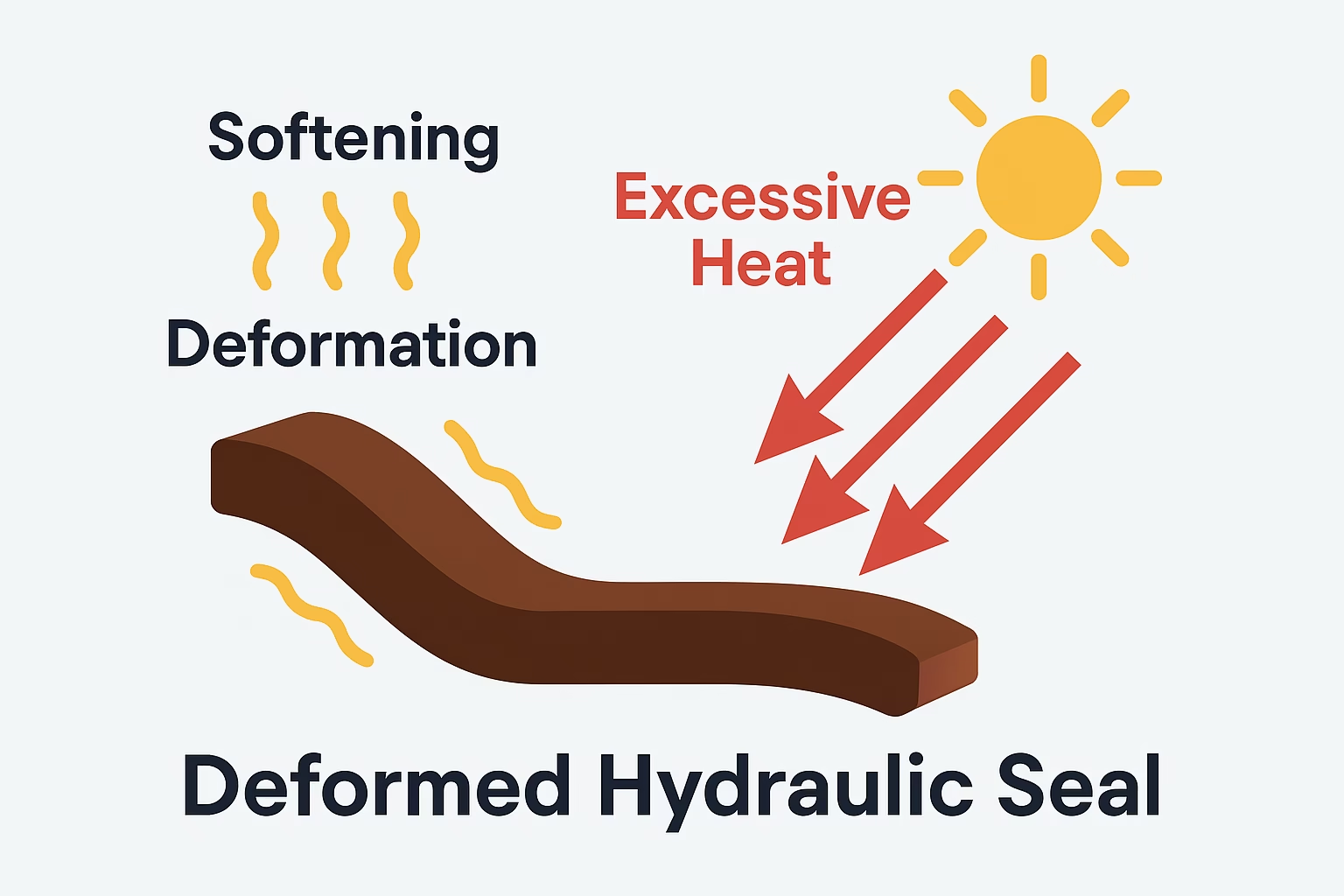

For example, selecting Inele O FKM in high-temperature environments ensures performance stability, while NBR may fail under the same conditions.

What factors should be considered when selecting a seal?

Sealing performance depends on multiple technical and environmental variables that must be evaluated at the time of selection.

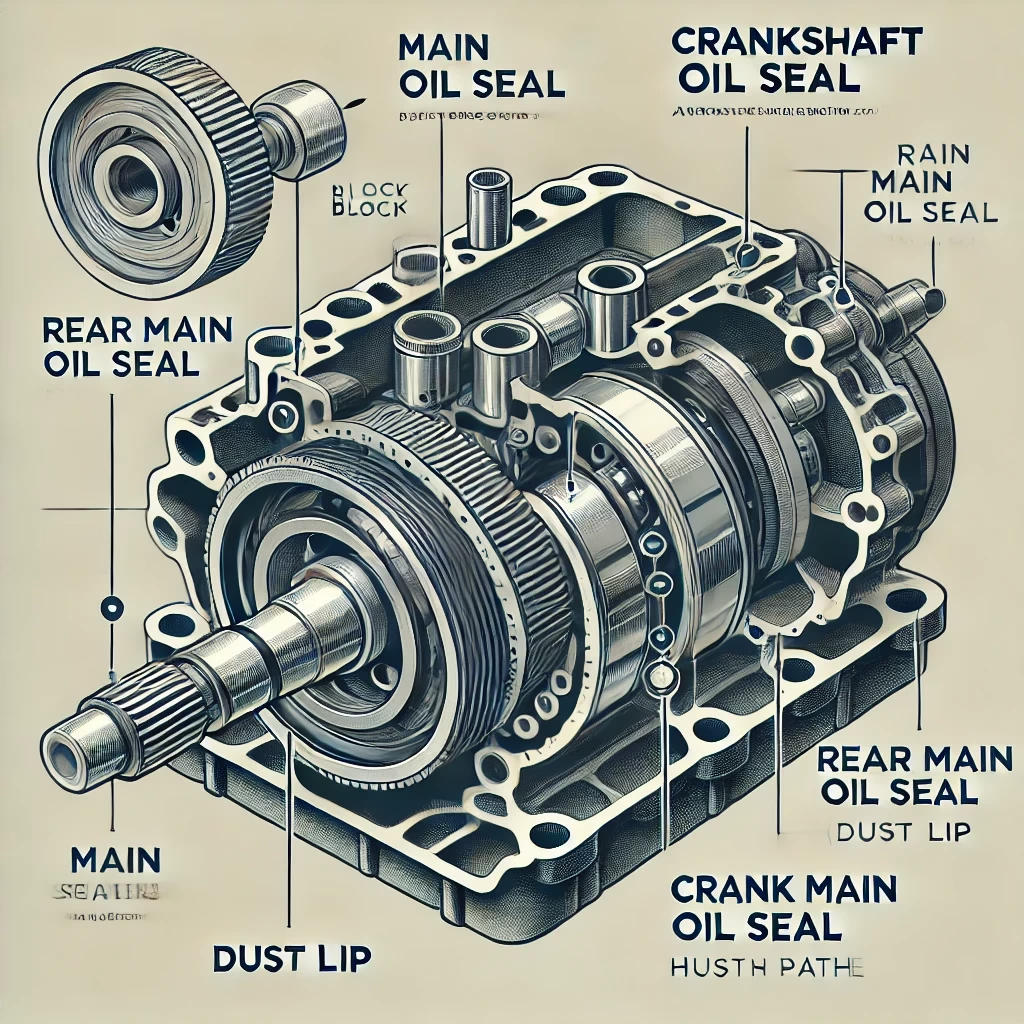

Key factors include media compatibility, operating temperature, pressure, motion type (rotary or reciprocating), surface finish, and installation environment.

Accurately defining these parameters allows for precise sealing component selection from options like Inele O, garnituri hidraulice, și garnituri de ulei.

How does material choice impact seal durability and uptime?

Each seal material responds differently to chemical exposure, temperature fluctuations, and mechanical stress.

Incorrect material selection leads to swelling, cracking, and loss of sealing force—directly reducing seal lifespan and increasing maintenance frequency.

Consulting comparison resources like FKM vs NBR Oil Seal helps maintenance teams select the best match for specific conditions.

How can standardization improve maintenance efficiency?

Using consistent seal types and sizes across multiple machines simplifies inventory management and accelerates replacements.

Standardizing seals reduces search time during breakdowns and ensures that spare parts are readily available when needed.

Maintenance departments often benefit from unified kits such as hydraulic seal kits categorized by application or size.

What role does seal supplier expertise play in uptime optimization?

Working with experienced sealing solution providers improves part selection and technical support, reducing trial-and-error replacements.

Expert suppliers offer guidance on correct sizing, customizations, and high-performance materials tailored to operational demands.

Reliable partners like Hengoseal provide fast, flexible solutions that minimize downtime by ensuring accurate fit, premium quality, and consistent delivery.

Concluzie

Seal selection is not a minor detail—it is a preventive strategy. Optimizing your seal choices reduces failure rates, shortens maintenance windows, and improves equipment reliability.

Need help selecting the right seals to reduce your operational downtime?

Hengoseal provides precision-engineered sealing components and technical guidance for critical equipment and high-demand applications.

E-mail: [email protected]

WhatsApp: +86 17622979498

Related topic

- Top 7 Causes of Seal Failure & How to Prevent Them (2025 Guide)

- Defecțiuni obișnuite ale etanșării hidraulice și cum să le preveniți

- O-Ring Buying Guide: How to Choose the Perfect Seal for Your Needs

- Cum să prelungești durata de viață a etanșărilor arborelui rotativ?