If your motor or pump system is running under presiune extremă, a standard oil seal won’t cut it. I’ve learned that garnituri de ulei de înaltă presiune aren’t just optional—they’re essential to keep machines running without costly leaks or breakdowns.

High-pressure oil seals protect your equipment by retaining lubrication, blocking contaminants, și withstanding pressure surges that destroy normal seals.

Let’s dive into how to choose and apply the right high-pressure seal for motors, pumps, and more.

What is a high-pressure oil seal and how does it work?

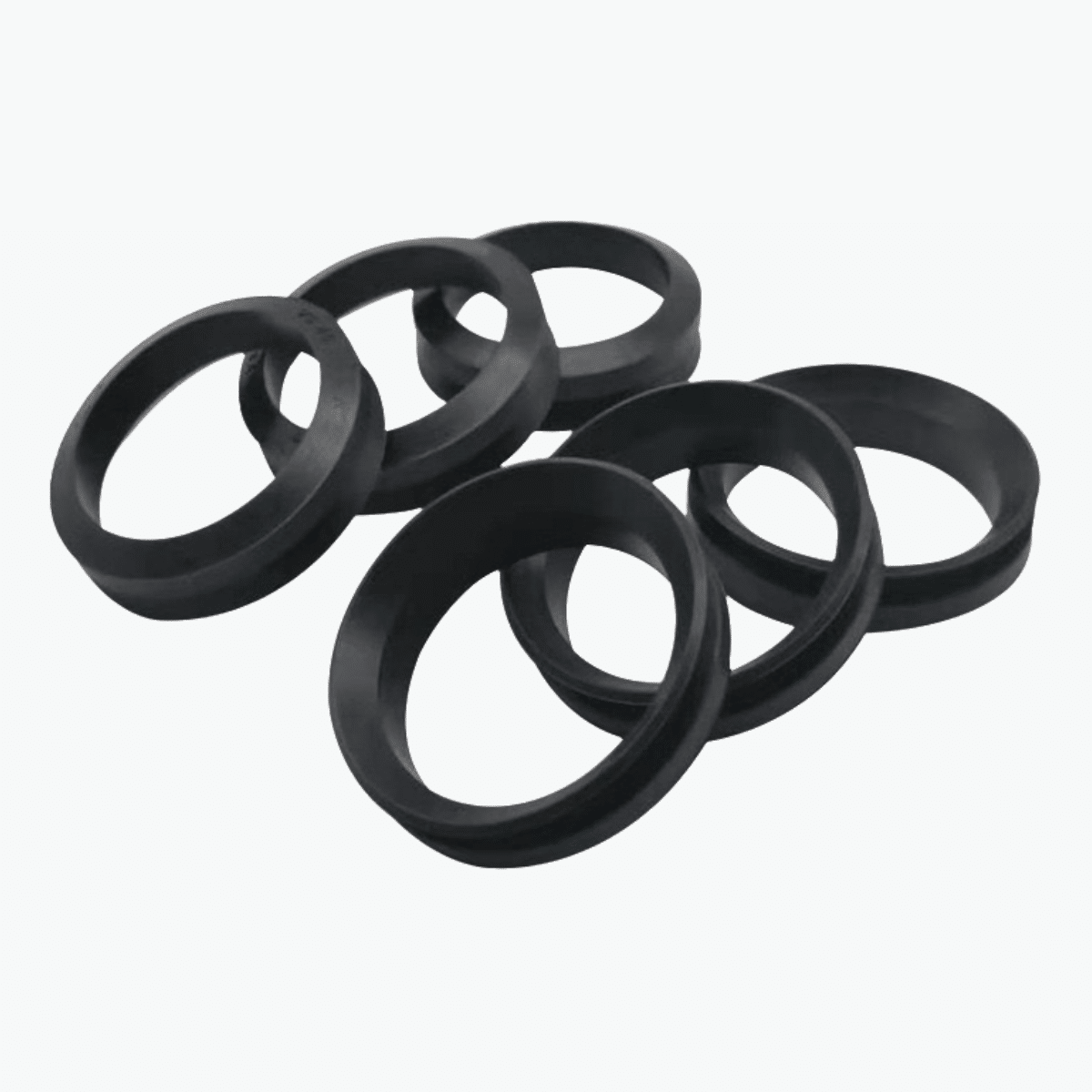

A high-pressure oil seal is designed to endure greater pressure, speed, and load than a standard seal.

It prevents fluid loss and contamination, which could otherwise ruin expensive rotating components.

High-pressure rotary shaft seals are reinforced with NBR, FKM, or PTFE to resist heat, oil, and wear. These seals are common in hydraulic pumps, gearboxes, și industrial motors, especially where failure isn’t an option.

Want to see the difference in design? Read our TC oil seal structure guide.

Why are high-pressure oil seals critical in motors and pumps?

Because motors and pumps generate high torque and fluid pressure, they need seals that can handle stress.

Standard seals may fail—leading to oil leaks, heat buildup, and machine failure.

Here’s what I’ve found in real-world use:

- In gearboxes, pressure spikes often break weaker seals

- In pumps, leakage lowers system pressure, causing inefficiency

- In motors, friction from poor seals overheats the shaft

That’s why many OEMs rely on high-quality shaft oil seals built for endurance.

Which high-pressure oil seals perform best in industrial environments?

If you’re looking for specific models, here are my top two picks for motors and pumps:

1. TCV High-Pressure Seal

Cel mai bun pentru: Hydraulic pumps, gearboxes, compressors

- Reinforced sealing lip for tight oil retention

- Handles shock loads and pressure surges

- Made from FKM or NBR, depending on temp and fluid

👉 Shop the TG4 double-lip oil seal for heavy-duty use.

2. K-Type Oil Seal

Cel mai bun pentru: High-speed rotating motors

- Withstands friction and heat

- Works with aggressive hydraulic fluids

- Made from FKM for chemical and thermal resistance

Also check out our HINO OEM oil seals for reference.

How do I choose the right material for a high-pressure oil seal?

Choosing the wrong material leads to early failure. Here's a quick comparison:

| Material | Cel mai bun pentru | Strength |

|---|---|---|

| BNR | Oil & fuel systems | Low cost, good wear |

| FKM | Heat & chemicals | Excellent resistance |

| PTFE | Speed & friction | Long life, low drag |

Explore all options in our rotary oil seal selection.

What applications require high-pressure oil seals?

📌 You need high-pressure seals if your system includes:

- Gearboxes in automation equipment

- Hydraulic pumps with high PSI output

- Industrial motors that run hot and fast

- Compressors that cycle under constant load

For customized sealing, check out our custom-size oil seal solutions.

How can I extend the lifespan of high-pressure seals?

Even top-tier seals need care. I recommend:

- Choosing materials rated for your exact temperature and fluid

- Inspecting shaft and housing for scratches or misalignment

- Storing your seals properly (storage tips here)

- Replacing every 12–24 months, especially under full-time use

Want to avoid common failures? Read our guide on prolonging rotary seal life.

Concluzie

High-pressure oil seals are non-negotiable for reliable pump and motor operation. Choose seals with the right material, pressure rating, și speed capacity for fewer failures and longer service life.

Get help selecting the right high-pressure seal

📩 mail:[email protected]

📞 WhatsApp:+86 17622979498

Related post

- Etanșare TC: Structură, specificații și utilizări

- Cum să alegi etanșarea corectă a arborelui rotativ

- High-Quality Oil Seals for Hydraulic Shafts

- How to Extend the Lifespan of Rotary Seals

- Custom Size Oil Seals Guide