Are your automation systems losing efficiency due to seal failure or air leakage? Poor seal selection can cripple pneumatic performance. This guide reveals how to choose and maintain the right seals for automation.

Choosing the right pneumatic cylinder seals improves automation speed, stability, and lifespan — reducing downtime and keeping production lines moving.

In automated systems, a worn or incompatible seal can halt operations in seconds. With more manufacturers upgrading to smart factories, ensuring reliable pneumatic sealing is now more important than ever.

Why Pneumatic Cylinder Seals Matter in Automated Equipment?

Automation demands consistent linear motion. But air loss, friction, or seal swelling quickly lead to:

- Pressure drops

- Unstable stroke

- Cylinder sticking or failure

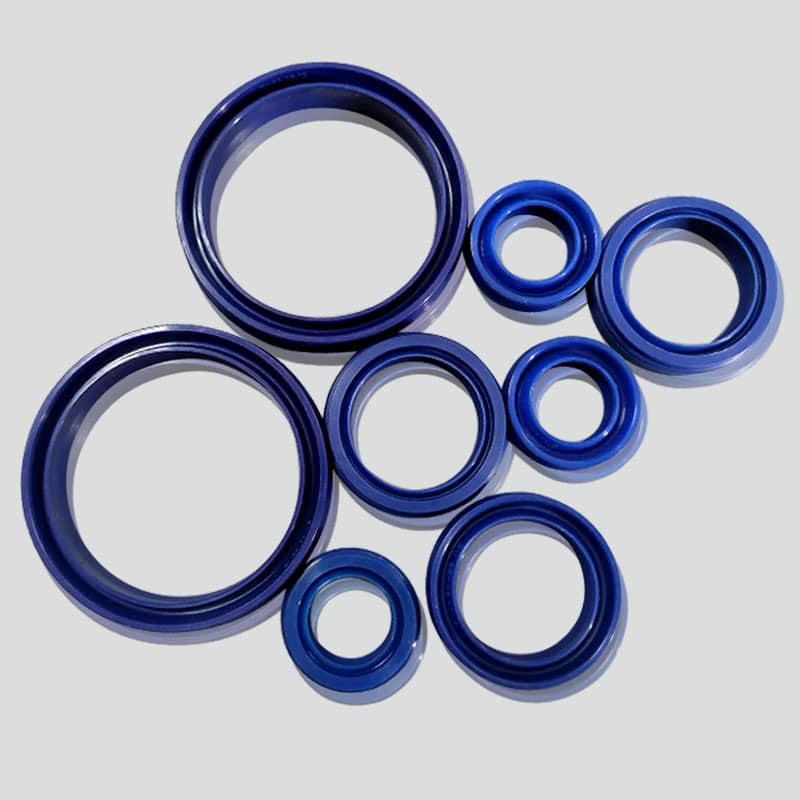

A well-chosen seal not only prevents air leaks but also reduces wear on cylinders and pistons. Hengoseal's pneumatic piston & rod seals are engineered for automation environments — from high-cycle robotics to precision presses.

How to Select the Right Pneumatic Seal for Automation Use?

Here’s a proven framework I use to match seals with automated systems:

| Factorul de selecție | De ce contează | Hengoseal Solution |

|---|---|---|

| Material | Affects durability & friction | NBR, TPU, FKM, PU, PTFE |

| Seal Profile | Matches stroke speed & load | U-cup, D-ring, compact seals |

| Interval de temperatură | Automation systems may run hot | Up to 200°C with FKM |

| Cycle Life | High repeat use needs robust seals | Tested 1M+ cycles |

| Compatibilitate cu lubrifierea | Avoids swelling or hardening | Oil-free or grease-resistant materials |

Oferim si noi a full guide to pneumatic cylinder seals that outlines application-specific sealing configurations.

Maintenance Tips to Extend Pneumatic Seal Life

Even the best seals fail early if not maintained correctly. Use these tips to extend service life:

- Keep cylinders clean – Dust and particles wear seals faster.

- Use filtered, dry air – Moisture degrades seals over time.

- Replace wiper seals regularly – Prevents dirt ingress into the cylinder.

- Check for pressure fluctuations – Spikes cause rapid wear.

- Avoid over-lubrication – Can swell or deform seals.

For example, we recently upgraded a client’s garnituri ștergătoare de praf in a packaging line. The result? 2× seal life and 15% fewer cylinder faults over 6 months.

Best Seal Materials for High-Speed Automation

Each automation environment demands specific properties:

| Material | Ideal pentru | Proprietăți |

|---|---|---|

| BNR | General use | Rezistent la ulei, rentabil |

| TPU | High-cycle speed | High wear resistance |

| FKM | Heat & chemicals | Temperature up to 200°C |

| PTFE | Dry run or no lubrication | Low friction, chemical-proof |

We help clients match material to motion specs — such as using Garnituri compacte KDAS in fast-stroke pneumatic cylinders.

Common Problems in Pneumatic Seals — and How to Fix Them

- Seal extrusion: Usually caused by oversized cylinder gaps or pressure spikes.

- Seal swelling: Caused by incorrect lubrication or chemical exposure.

- Hardening: Results from heat aging, especially with cheap materials.

- Compression set: Seal loses elasticity, causing air leaks.

The key is choosing the right material and profile from the start — not just reacting to failures.

Concluzie

Reliable pneumatic cylinder seals are the foundation of smooth, long-lasting automation. Choosing the right seal now prevents costly downtime later.

Related topic

Top Benefits of Pneumatic Cylinder Seals in 2025

5 Common Problems with Pneumatic Seals & How to Fix

TPU vs NBR: Which Seal is Best for Pneumatic Systems?

Let Your Automation Run Smoothly — Partner with Hengoseal

Need durable, low-friction pneumatic seals tailored for automation? We support custom profiles, low MOQ, and rapid global delivery.

Contactați-ne astăzi:

- E-mail: [email protected]

- WhatsApp: +86 17622979498

Get samples or a quote in 24 hours.