Pneumatic Seals

- 0 MOQ

- 3 DAYS DELIVERY

- 100% customer repurchase rate

Send your inquiry now !

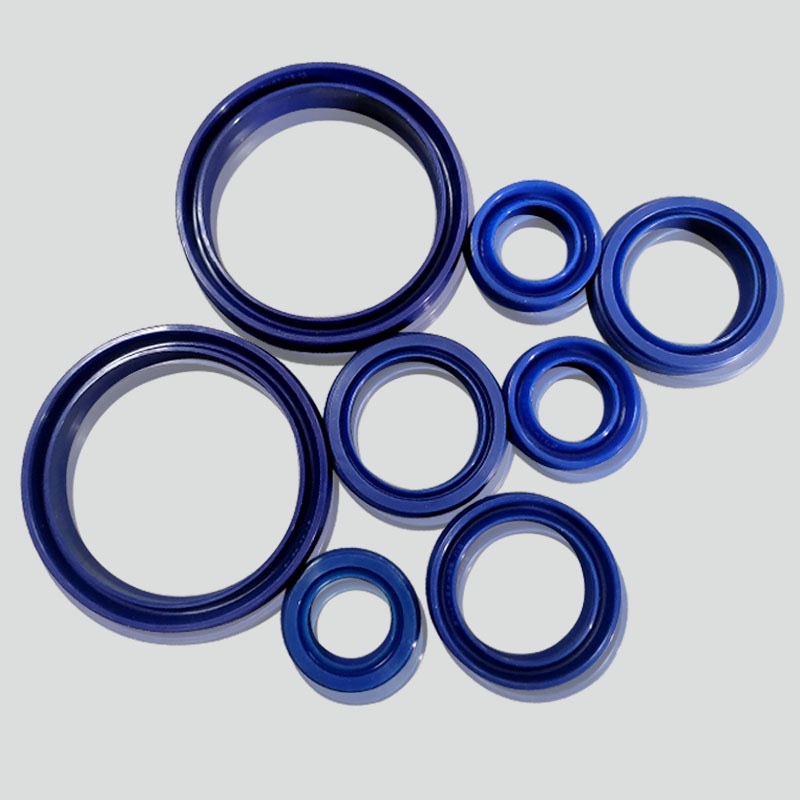

Pneumatic Seals

Pneumatic seals are specialized components designed to contain or control compressed air within cylinders, valves, and related equipment. By ensuring a tight seal, these parts help maintain consistent pressure, reduce energy loss, and prolong the service life of vital systems. At Hengoseal.com, we offer a wide array of pneumatic sealing solutions that suit diverse operational needs—whether you’re managing high-speed, high-frequency motions or precision systems requiring minimal leakage.

@buyer Mehr lesen

I've been working with Hengoseal for over three years, and it's been a great experience throughout. Their product quality is consistently reliable, the pricing is reasonable, and they always deliver on time. Even when I have smaller orders, they’re very supportive — which I truly appreciate.

Product Details

- Y-QYD Piston Hole Seal (NBR/FKM/TPU)

Provides airtight sealing for piston-hole interfaces, balancing durability and flexibility. - QYD Shaft Seal (NBR/FKM/TPU)

Ideal for shaft applications, preventing compressed air escape and external contaminants ingress. - COP Piston Seal (NBR/FKM)

A reliable solution for standard piston applications, offering excellent sealing performance in moderate temperatures. - Z8 Piston Seal (NBR/FKM/TPU)

Versatile design that adapts to varying pressure levels, ensuring stable motion control. - Z5 & ZT Piston Seals (NBR/FKM)

Streamlined shapes suitable for cylinders requiring low friction and minimal air leakage. - KDN & PZ Piston Seals (NBR/FKM)

Deliver strong sealing stability in repetitive motion tasks, especially beneficial in automation. - PPD Piston Seal (NBR/FKM)

Employs a robust lip structure to handle fluctuations in air pressure without compromising performance. - MYA Flat Mouth Dust Seal (NBR/FKM)

Shields internal components from dust and debris, maintaining pneumatic system cleanliness. - E4 Piston Y-Type Seal (NBR/FKM)

Classic Y-shaped geometry for versatile piston sealing, ideal for standard cylinders. - ZHM Dust Seal (NBR/FKM/TPU) & EM Dust Seal (TPU)

Engineered to keep fine particles and moisture at bay, extending system longevity. - DOP Dust Seal (NBR/FKM)

Helps maintain pneumatic cylinder integrity by minimizing external contamination. - PP Flat Edge & PP Kaifu (NBR/FKM/TPU)

Multifunctional designs that adapt to various pneumatic configurations and speed requirements. - DK, DE, DP Whole Pistons (NBR)

Integrated piston designs offering consistent, leak-free operation in lightweight setups. - DSBC Piston Plate (TPU) & DPRS Piston Seal (TPU)

Durable options catering to high-frequency cycles, reducing wear and tear in demanding environments. - DNC Winding Cushion (NBR), Yaderong Winding Cushion (TPU), PA Winding Ring (NBR)

Absorb shocks and vibration, enhancing control and stability in pneumatic systems. - CSP Electromagnetic Valve Flat Pad (TPU/NBR/FKM)

Maintains precision in valve operations by ensuring a secure, airtight seal.

Material Advantages

- NBR (Buna-N): Reliable oil and fluid resistance, well-suited for typical pneumatic conditions.

- FKM (Viton®): Delivers excellent chemical and heat resistance for more demanding settings.

- TPU (Thermoplastic Polyurethane): Offers exceptional abrasion resistance and flexibility in high-frequency piston movements.

These materials can be combined or chosen based on your system’s temperature range, operating pressure, and frequency of use, ensuring optimal performance and durability.

Applications of Pneumatic Seals

- Pneumatic Cylinders: Provide efficient linear or rotary motion control.

- Valves and Actuators: Ensure precise control over airflow and pressure regulation.

- Automation Equipment: Minimize leakage for faster cycle times and energy savings.

- Packaging & Material Handling: Maintain smooth, reliable operation in dusty or moisture-prone environments.