Noticed oil dripping under your machine or car? That small leak could point to a failing oil seal—a simple part with a critical role.

Oil seal leaks are one of the most common maintenance headaches in industrial, automotive, and hydraulic systems. Ignoring them can lead to oil loss, pressure drop, and severe equipment damage.

In this article, I’ll show you the main causes, early warning signs, and best ways to fix oil seal leaks—before they cost you downtime or dollars.

What causes an oil seal to leak?

Oil seal leaks are usually caused by one of the following:

| Cause | Description |

|---|---|

| Wear and Tear | Natural aging of the rubber lips |

| Improper Installation | Wrong orientation or uneven seating |

| Shaft Damage | Scratches or eccentric motion cuts the lip |

| Overpressure | Seal not rated for system pressure |

| High Heat or Chemicals | Material not suited for the application |

| Contamination | Dirt damages lip and sealing surface |

Poor alignment or using the wrong seal type (e.g. TC in a dusty system instead of TG4) also leads to premature failure.

👉 Learn proper installation here: Oil Seal Installation Guide

What are the symptoms of a leaking oil seal?

Here’s how to spot trouble early:

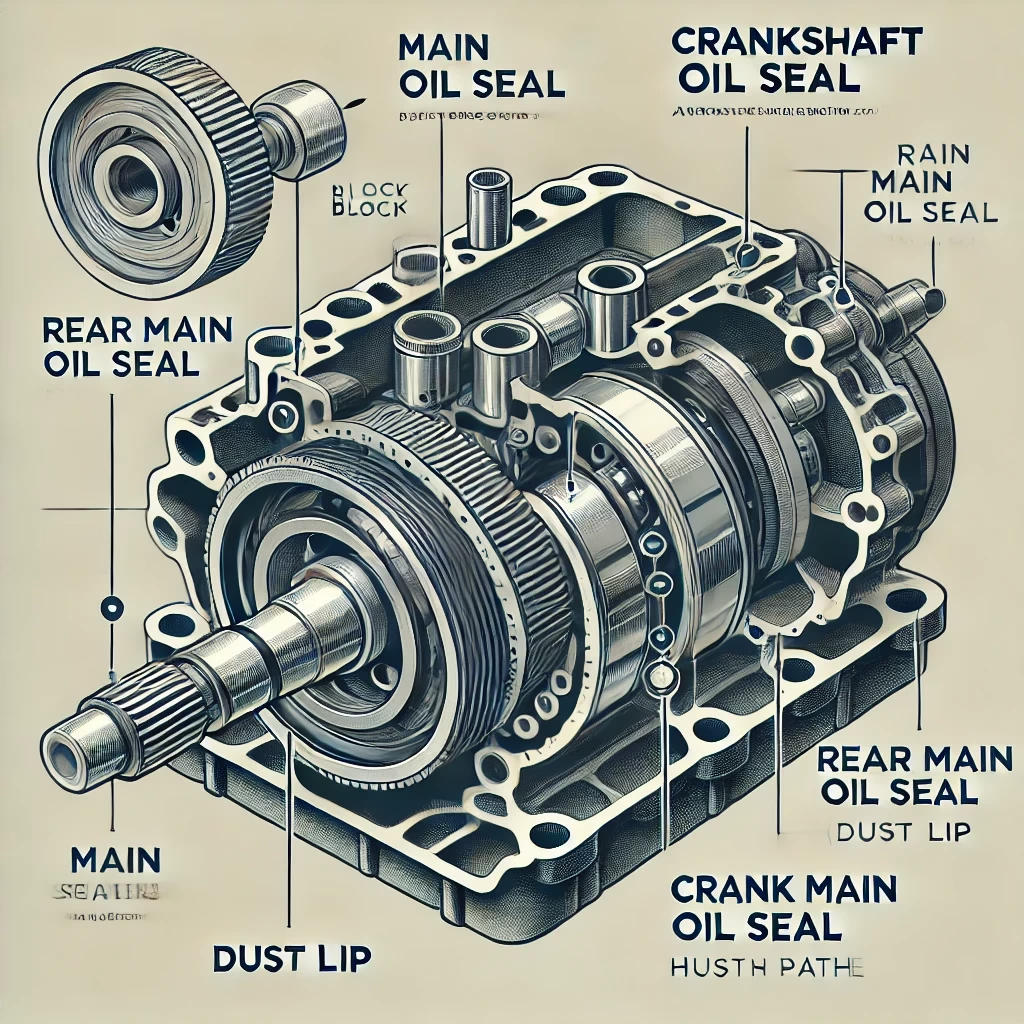

- Oil dripping near the crankshaft, camshaft or gearbox

- Wetness around the shaft area

- Low oil levels or warning lights

- Unusual noise or vibration

- Greasy buildup on nearby parts

- Burning oil smell (in automotive)

If you see these, inspect your seals immediately—especially if you haven’t changed them for years.

👉 For engine-specific leaks, see: Crankshaft Oil Seal Replacement Guide

Can oil seal leaks be repaired or must the seal be replaced?

Unfortunately, you can’t “fix” an oil seal—it must be replaced.

There are temporary additives that claim to swell rubber lips, but these are short-term patches at best.

Here’s what to do instead:

- Identify the leaking seal

- Confirm shaft or housing isn’t damaged

- Select a replacement based on size and material

- Install a new seal properly

- Run test and monitor

Need a replacement fast? Check out our:

- TC Oil Seal – Double Lip, Metal Shell

- TG4 Oil Seal – Dust-Proof Skeleton Design

- Toyota Crankshaft Seals

What’s the best way to prevent oil seal leaks?

Prevention beats repair. Here's what works:

- Use the right material: NBR for oils, FKM for heat or chemicals

- Choose the right seal structure: TG4 for dusty systems, TC for rotary shafts

- Install seals carefully with a driver tool

- Lubricate lips before installation

- Inspect shafts regularly for damage or grooves

- Replace during major maintenance—not after failure

👉 Read: TG4 Oil Seal Guide

👉 Compare materials: FKM vs NBR: Which Should You Use?

When should I replace a leaking oil seal?

Here are three golden rules:

- Immediately if the leak is active or dripping

- During planned maintenance if you notice any seepage

- Before long operation cycles (e.g. seasonal machine startup)

Don’t wait until the leak worsens—it may damage the shaft or housing, increasing repair cost.

Need help selecting the right replacement? Contact us with shaft size, application, or OEM part number.

Conclusion

Oil seal leaks may start small—but if ignored, they can bring machines or vehicles to a stop. Replace faulty seals early with the right material, structure, and fit.

Call to action

Need a fast replacement for your leaking oil seal? Hengoseal offers TC, TG4, Toyota crankshaft and other shaft seals in both NBR and FKM.

📧 Email: [email protected]

📱 WhatsApp: +86 17622979498