O-Ring Solutions Hub | Types, Selection & Kits (2025)

Discover reliable O-Ring options for your hydraulic, automotive, and industrial needs. Browse by type, material, or application—all in one place.

Table of Contents

O-Ring Basics: What They Are & Why They Matter

An O-Ring is a small but critical sealing component used across industries—from hydraulics to food equipment. Its round shape compresses under pressure to block leaks of fluid or gas. This simple seal plays a vital role in reducing downtime, ensuring safety, and maintaining system efficiency.

👉 Want to understand how O-Rings work and where they’re used? Check our full guide:

How to measure o rings?

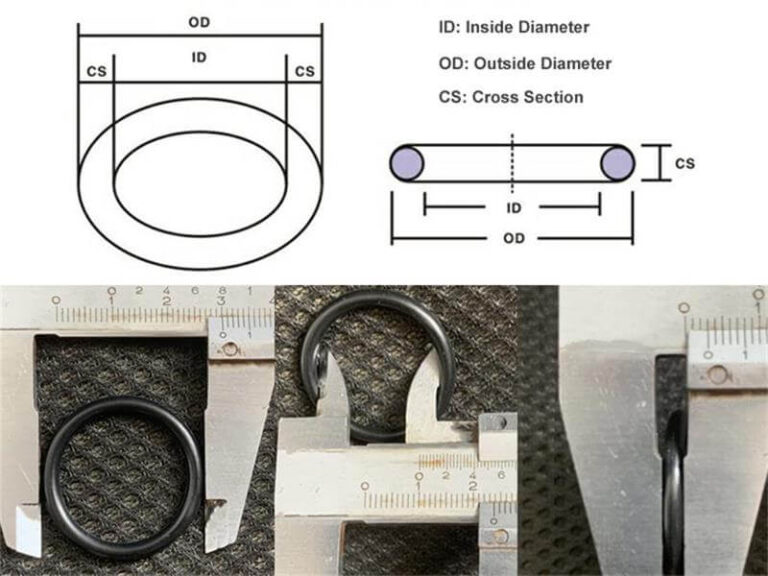

To measure an O-Ring correctly, use a digital caliper to check three dimensions:

ID (Inside Diameter), OD (Outside Diameter), and CS (Cross Section).

Even a small mistake can lead to leakage or system failure, so precision matters.

Most standard O-Ring kits follow ISO or AS568 sizing. For non-standard or unknown seals, send us your sample or dimensions—we’ll help you identify and replace it correctly.

👉 Step-by-step instructions here:

O-Ring Material Comparison: Which One Should You Choose?

Choosing the right O-Ring material is key to long-term sealing performance. Different applications require different properties—chemical resistance, temperature tolerance, elasticity, or food-grade compliance.

Here’s how common materials compare:

💡 Still unsure?

FKM (Viton®): Excellent resistance to heat, fuel, and aggressive chemicals

NBR (Nitrile): Great for oil-resistant sealing in automotive and industrial use

Silicone: FDA-approved, flexible, and ideal for food and pharma

EPDM: Performs well in steam, water, and outdoor environments

FKM vs NBR: Which material works better for oil resistance and high temperature?

Silicone vs NBR: Do you need flexibility or fuel compatibility?

Silicone vs FKM: Comparing heat resistance and FDA compliance.

Buna vs Nitrile: Are they the same? What's better for chemical sealing?

Buna-N vs EPDM: Which is more suitable for steam, water, and outdoor use?

EPDM vs Silicone: Choosing between outdoor durability and flexibility.

EPDM vs FKM: When to use EPDM over fluorinated rubber in dynamic seals?

Fluorocarbon vs FKM: What's the real difference and compatibility scope?

O-Ring Material Performance Comparison: What’s Best for Your Application?

Different sealing environments demand different materials. Not sure if you need FKM, NBR, Silicone, or EPDM? Explore these material vs material matchups to decide what’s best for your fluid, temperature, and chemical resistance needs:

🛠️ Need help choosing?

Tell us your working conditions, and we’ll match the right material for your seal:

O Ring Applications

O-Rings are used across a wide range of industries—from high-pressure hydraulics to food-grade processing. Each application presents its own challenges like chemical resistance, heat tolerance, or dynamic motion. Below are the most common scenarios and how to choose the right O-Ring material and profile.

High-Pressure / High-Temperature O RING

In extreme environments like hydraulics or steam systems, O-Rings must resist high heat and intense pressure. FKM and PTFE materials are often preferred for these demanding applications.

Hydraulic O RING & Fittings

Hydraulic systems rely on O-Rings to prevent leaks in cylinders, valves, and couplings. Choosing the right profile and material helps maintain performance over thousands of cycles.

Automotive & Engine Systems O Ring

O-Rings are widely used in fuel injectors, pumps, filters, and cooling systems. Kits with multiple sizes allow quick replacements for various car brands.

Food & Beverage Applications O Ring

Food-grade O-Rings must meet FDA/NSF standards and resist frequent cleaning with steam or chemicals. Silicone and EPDM are ideal for sanitary sealing.

Essential O-Ring Kits & Assortments: Find the Right Set for Any Task

Whether you’re maintaining a hydraulic press, fixing automotive systems, or stocking emergency repair kits, O-Ring assortments help you seal with speed and precision. Explore by use case to find the most suitable option.

🔧 General Maintenance & Industrial Use

⚙️ Equipment Fit & Size Selection

🔥 Extreme Temperature or Chemical Environments

🚗 Automotive & Fluid Systems

📦 MOQ & Supplier Sourcing

🛠️ Specialized Repair Kits for Engines & Pressure Equipment

🎯 Need a quote or want to request a custom kit?

How to Choose the Right O-Ring and Control Your Costs?

Make smarter O-Ring decisions—compare options, avoid overpaying, and get the right seal every time.

Finding the right O-Ring shouldn’t be confusing or expensive. In this section, we break down how to:

Match materials and dimensions with your application.

Compare prices across sizes and materials.

Choose between custom vs. standard options.

Avoid common selection mistakes that cost time and money.

Recommended O-Ring Products

We offer high-quality O-rings in NBR, FKM, FFKM, EPDM, silicone, and other materials. Explore our full range of O-ring products for more details.