Seal failures are expensive. The wrong O-ring material can cause unplanned downtime, costly repairs, and even safety risks. Choosing the right material not only prevents failures but can extend equipment life and cut annual maintenance costs by thousands of dollars.

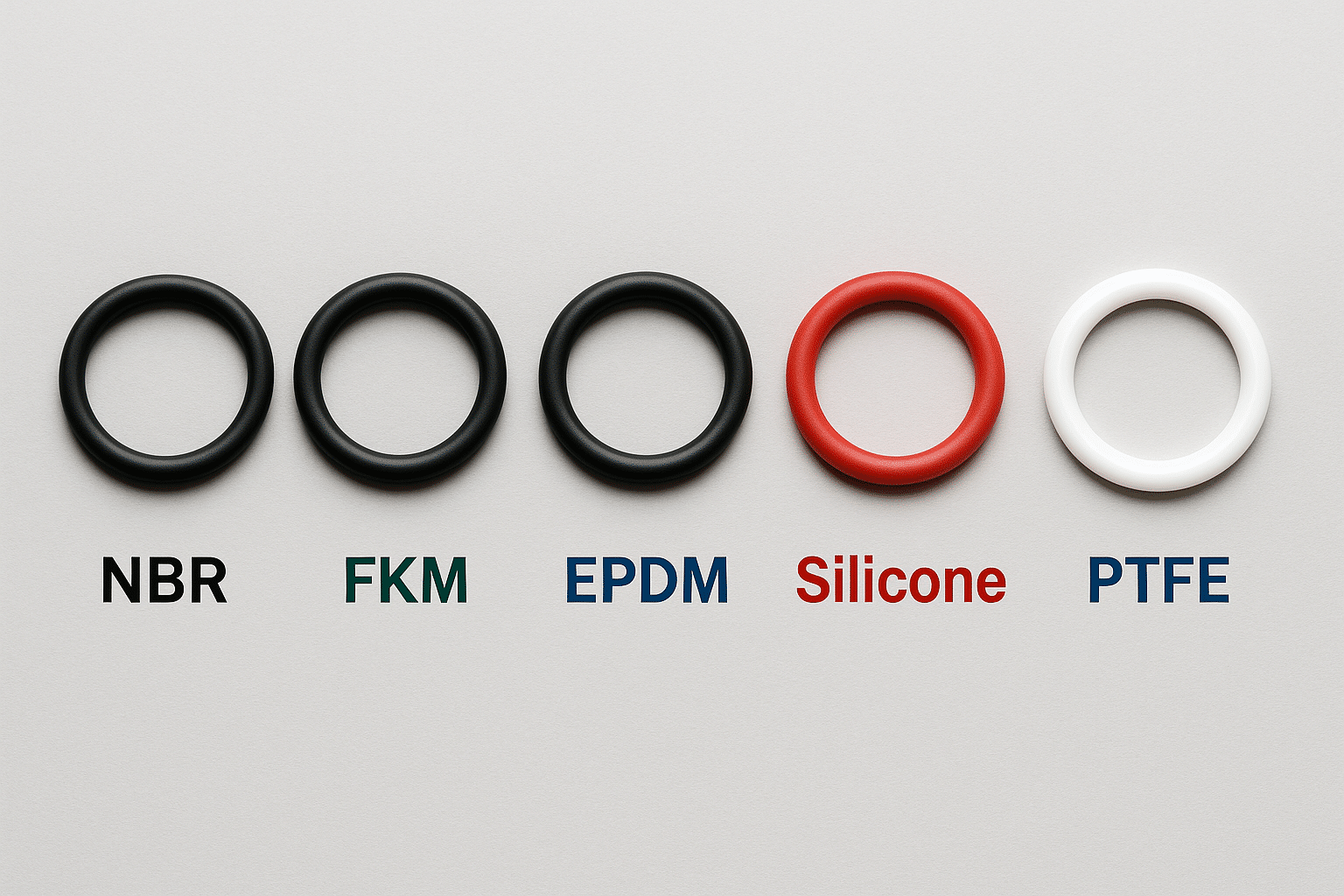

This technical + procurement guide compares the five most widely used industrial O-ring materials — NBR, FKM, EPDM, Silicone, and PTFE — with detailed performance data, chemical compatibility charts, real-world industry cases, and expert sourcing tips for global buyers.

For a complete overview of O-ring types, materials, and industry-specific sealing solutions, explore our Comprehensive O-Ring Solutions Hub.

What Are the Key Differences Between NBR, FKM, EPDM, Silicone & PTFE O-Rings?

Before selecting an O-ring material, global buyers should understand how each elastomer performs in terms of temperature range, chemical resistance, oil compatibility, hardness, and industry certifications.

| Material | Temp Range (°C / °F) | Chemical Resistance | Oil Resistance | Hardness (Shore A) | Common Colors | Certifications |

|---|---|---|---|---|---|---|

| NBR | -40 to +100 / -40 to +212 | Moderate | Excellent | 60–90 | Black, Brown | FDA (optional) |

| FKM | -20 to +205 / -4 to +401 (up to 230 / 446 short-term) | Excellent | Excellent | 60–90 | Brown, Green | FDA, WRAS |

| EPDM | -50 to +150 / -58 to +302 | Excellent | Poor | 50–90 | Black | FDA, WRAS, NSF |

| Silicone | -60 to +200 / -76 to +392 | Good | Moderate | 40–80 | Red, White | FDA, NSF |

| PTFE | -200 to +260 / -328 to +500 | Excellent | Excellent | — | White | FDA |

For a detailed side-by-side performance comparison of NBR, FKM, EPDM, Silicone, and PTFE, visit our O-Ring Material Selection & Comparison Guide.

Which O-Ring Material Offers the Best Chemical Compatibility for Industrial Applications?

If your equipment is exposed to fuels, acids, steam, or aggressive chemicals, chemical compatibility is the first factor to consider. The table below compares resistance of the five major O-ring materials to over 15 common industrial media.

| Chemical / Fluid | NBR | FKM | EPDM | Silicone | PTFE |

|---|---|---|---|---|---|

| Gasoline | ✔️ | ✔️ | ❌ | ❌ | ✔️ |

| Diesel Fuel | ✔️ | ✔️ | ❌ | ❌ | ✔️ |

| Engine Oil | ✔️ | ✔️ | ❌ | ❌ | ✔️ |

| Hydraulic Oil (Petroleum-based) | ✔️ | ✔️ | ❌ | ❌ | ✔️ |

| Synthetic Hydraulic Fluids | ❌ | ✔️ | ✔️ | ❌ | ✔️ |

| Brake Fluid (Glycol-based) | ❌ | ❌ | ✔️ | ❌ | ✔️ |

| Water | ✔️ | ✔️ | ✔️ | ✔️ | ✔️ |

| Steam (up to 150°C) | ❌ | ❌ | ✔️ | ❌ | ✔️ |

| Mild Acids | ❌ | ✔️ | ✔️ | ❌ | ✔️ |

| Strong Acids | ❌ | ✔️ | ❌ | ❌ | ✔️ |

| Alkalis | ❌ | ✔️ | ✔️ | ❌ | ✔️ |

| Alcohols | ✔️ | ✔️ | ✔️ | ✔️ | ✔️ |

| Ketones | ❌ | ❌ | ✔️ | ❌ | ✔️ |

| Amines | ❌ | ❌ | ✔️ | ❌ | ✔️ |

| Aromatic Solvents | ❌ | ✔️ | ❌ | ❌ | ✔️ |

| Chlorinated Solvents | ❌ | ✔️ | ❌ | ❌ | ✔️ |

| Oxygen | ❌ | ✔️ | ✔️ | ✔️ | ✔️ |

| Refrigerants (HFCs) | ❌ | ✔️ | ✔️ | ✔️ | ✔️ |

How to Select NBR O-Rings for Oil & Fuel Applications?

If your application involves petroleum-based oils or fuels, NBR O-rings offer the best balance of cost and oil resistance.

Variants:

- Standard NBR – Reliable for most oil and fuel applications.

- Low-Temp NBR – Maintains flexibility down to -50°C.

- Hydrogenated NBR (HNBR) – Greater heat and ozone resistance.

Common Failures: Hardening or cracking when exposed to ozone or prolonged high temperatures.

Applications:

- Hydraulic pumps & cylinders

- Pneumatic tools

- Automotive fuel systems

Industry Case:

A construction equipment OEM replaced EPDM with NBR in hydraulic couplings, cutting seal costs by 20% without reducing service life.

Related Links:

- Explore our Nitrile O-Rings for Oil & Fuel Applications – ideal for hydraulic systems, automotive fuel lines, and industrial sealing.

- Check our Complete O-Ring Assortment Kits – perfect for maintenance teams and on-site repairs.

Why Choose FKM (Viton®) O-Rings for Harsh Environments?

When heat, chemicals, and fuels are all present, FKM is the go-to choice. It resists swelling, maintains elasticity, and operates at temperatures up to 205°C.

Variants:

- Standard FKM – Broad chemical resistance.

- Low-Temp FKM – Down to -40°C.

- Specialty Grades – Improved amine or ketone resistance.

Common Failures: Swelling in certain ketones/amines if the wrong grade is selected.

Applications:

- Aerospace hydraulics

- Chemical process pumps

- Automotive engine seals

Industry Case:

A refinery upgraded from NBR to FKM in fuel pump seals, extending life by 4x and saving $30,000/year in downtime.

Related Links:

- Browse our High-Temperature & Chemical-Resistant FKM O-Rings – perfect for aerospace, chemical processing, and automotive engine sealing.

- Try our Custom O-Ring Maker Kits – create any size seal on demand for urgent repairs and prototyping.

When Should EPDM O-Rings Be Used in Water, Steam & Outdoor Systems?

If your sealing application involves drinking water, steam, or outdoor exposure, EPDM provides excellent weather, ozone, and UV resistance.

Variants:

- Peroxide-Cured EPDM – Enhanced heat resistance.

- Sulfur-Cured EPDM – Lower cost, standard performance.

Common Failures: Swelling in petroleum-based fluids.

Applications:

- Drinking water systems

- Steam sterilization equipment

- Outdoor energy infrastructure

Industry Case:

A power plant switched to EPDM in boiler steam systems, extending replacement cycles from 6 months to 18 months.

Related Links:

- Discover our EPDM O-Rings for Water, Steam & Outdoor Sealing – ideal for potable water systems, steam sterilization, and weather-exposed equipment.

Why Silicone O-Rings Are Ideal for Extreme Temperature & Food Applications?

For food processing, medical devices, and electronics, Silicone O-rings offer exceptional flexibility from -60°C to +200°C while meeting FDA and NSF requirements.

Variants:

- High-Strength Silicone – Improved tear resistance.

- Platinum-Cured Silicone – Superior purity for sanitary use.

Common Failures: Tearing under high dynamic loads, swelling in fuels.

Applications:

- Food & beverage equipment

- Medical devices

- Electronics sealing

Industry Case:

A bakery equipment maker used platinum-cured silicone for oven gaskets, meeting FDA standards and cutting maintenance downtime by 30%.

Related Links:

- View our Silicone O-Rings for Extreme Temperatures & Food-Grade Applications – perfect for food processing equipment, medical devices, and electronics sealing.

Why PTFE O-Rings Dominate in Extreme Chemical & Temperature Applications?

In chemical processing, cryogenics, and high-temperature applications, PTFE is unmatched for chemical inertness and temperature range.

Variants:

- Virgin PTFE – Maximum chemical resistance.

- Filled PTFE (Glass, Carbon) – Enhanced wear resistance.

Common Failures: Cold flow under load; solved with spring energizers.

Applications:

- Chemical tanks

- Semiconductor etching

- Cryogenic equipment

Industry Case:

A semiconductor facility achieved 18 months of zero degradation by replacing elastomer seals with PTFE.

Related Links:

- Explore our PTFE O-Rings for Extreme Chemicals & Wide Temperature Ranges – ideal for chemical processing, cryogenic equipment, and high-purity sealing applications.

Which O-Ring Material Performs Best for Temperature Range & Service Life?

Temperature and expected service life are critical for ROI on sealing components.

| Material | Min Temp (°C/°F) | Max Continuous (°C/°F) | Short-Term Peak (°C/°F) | Typical Static Life* | Typical Dynamic Life* | Recommended Shore A |

|---|---|---|---|---|---|---|

| NBR | -40 / -40 | +100 / +212 | +120 / +248 | 3–5 years | 1–2 years | 70 (general), 90 (high-pressure) |

| FKM (Viton®) | -20 / -4 | +205 / +401 | +230 / +446 | 5–10 years | 2–4 years | 75 (general), 90 (high-temp) |

| EPDM | -50 / -58 | +150 / +302 | +170 / +338 | 5–8 years | 2–3 years | 70 (water), 80 (steam) |

| Silicone | -60 / -76 | +200 / +392 | +230 / +446 | 4–7 years | 1–2 years | 50–70 (static preferred) |

| PTFE | -200 / -328 | +260 / +500 | +280 / +536 | 10+ years | 4–6 years | — (spring-energized) |

*Values assume correct groove design, compatible media, proper compression set, and normal duty cycles.

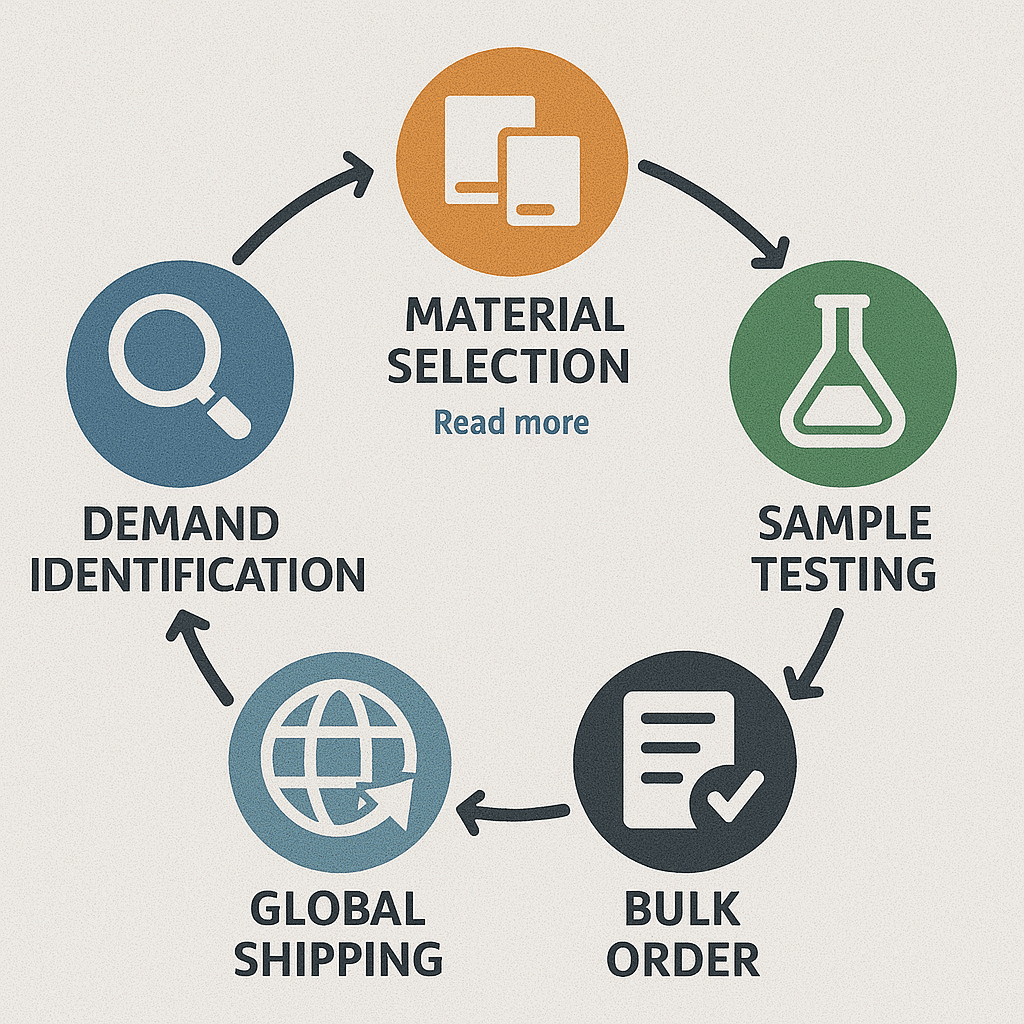

How Should Global Buyers Select the Right Industrial O-Ring?

When sourcing industrial O-rings for global applications, following a structured procurement process can save time, cost, and prevent failures:

- Define application requirements – Identify operating temperature, pressure, fluid type, and environmental conditions.

- Select the right O-ring material – Match fluid compatibility and temperature range using our chemical resistance chart.

- Check relevant certifications – For regulated industries, verify FDA, WRAS, or NSF compliance.

- Confirm dimensional standards – Ensure compatibility with ASTM D2000, ISO 3601, or SAE AS568.

- Evaluate cost-to-performance ratio – Choose materials that meet your needs without overspecifying.

- Verify supplier flexibility – Ensure your O-ring supplier can provide no-MOQ orders, fast delivery, and custom manufacturing if required.

What Should Buyers Remember Before Purchasing Industrial O-Rings?

Before placing an order, keep these key points in mind:

- NBR O-rings – Best for oils and fuels; cost-effective and widely available.

- FKM O-rings – High chemical and heat resistance; ideal for harsh environments.

- EPDM O-rings – Excellent water and steam sealing; poor oil resistance.

- Silicone O-rings – Wide temperature range; suitable for food and medical applications.

- PTFE O-rings – Extreme chemical resistance; best for aggressive fluids and cryogenics.

Balancing performance, compliance, and budget is essential in any O-ring buying guide. Always work with a trusted industrial sealing solutions provider to ensure quality and longevity.

Why Global Buyers Choose Hengoseal for Industrial O-Rings

At Hengoseal, we combine technical expertise with flexible production to deliver O-rings and sealing solutions that meet the demands of industries worldwide:

- No MOQ – Order exactly what you need, from small trial runs to bulk shipments.

- Fast global delivery – Stock items ship in 3–7 days; custom orders in 10–15 days.

- Wide material selection – NBR, FKM, EPDM, Silicone, PTFE, and specialty compounds.

- Custom manufacturing – Tailored sizes, hardness, and packaging to your specifications.

- Certified quality – Compliance with FDA, WRAS, NSF, ASTM, ISO, SAE standards.

- Proven reliability – 95%+ repeat order rate from global clients.

Whether you need standard sizes or engineered solutions, Hengoseal is your trusted O-ring supplier for industrial and commercial applications.

Ready to Source Industrial O-Rings with No MOQ?

If you’re looking for a reliable industrial O-ring supplier with global delivery, certified quality, and flexible order quantities, Hengoseal is ready to support your sealing needs.

- No MOQ – Order exactly what you need, from small batches to large production runs.

- Fast global delivery – Stock items ship in 3–7 days; custom O-rings in 10–15 days.

- Full material range – NBR, FKM, EPDM, Silicone, PTFE, and specialty compounds.

- Custom solutions – Tailored sizes, hardness, colors, and packaging.

- Certified quality – FDA, WRAS, NSF, ASTM, ISO, SAE compliance.

- Trusted worldwide – 95%+ repeat order rate from global industrial buyers.

📧 Email: [email protected]

📱 WhatsApp: +86 17622979498

Looking for more insights on O-ring materials and industrial sealing solutions? Explore these related guides:

- O-Ring Solutions Hub – Comprehensive guide to O-ring types, uses, and industry applications.

- O-Ring Material Comparison Guide – Side-by-side material performance data.

- Nitrile O-Rings Detailed Guide – Best practices for oil and fuel applications.

- FKM O-Rings High Temperature Sealing Guide – For chemical and heat-intensive environments.

- EPDM O-Rings Selection Guide – For water, steam, and outdoor sealing.