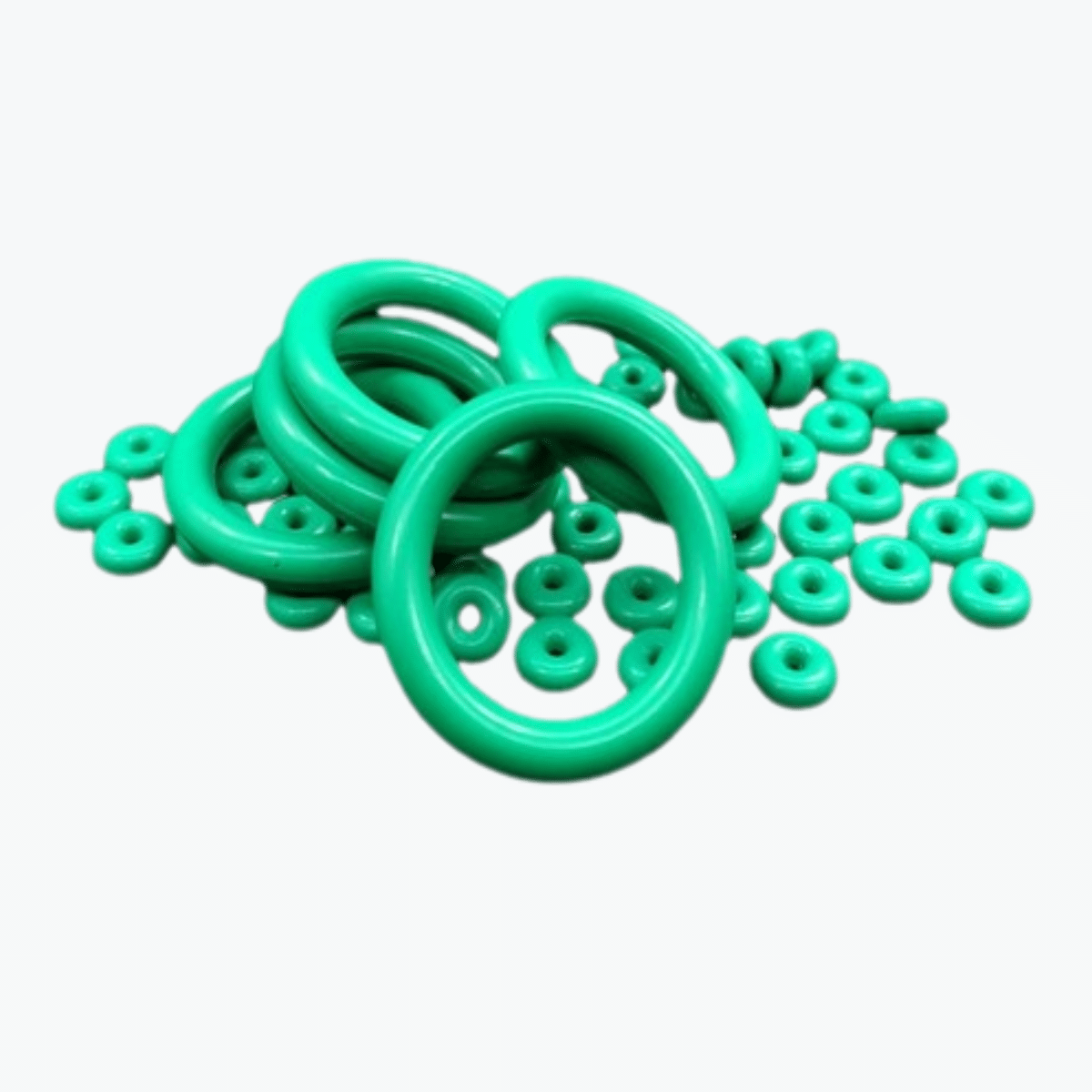

Hydraulic seals often fail under pressure — literally. I’ve learned that selecting the right high-pressure hydraulic O-ring can make or break your system.

When it comes to durability, you need seals that can handle both brutal PSI ഒപ്പം aggressive fluids. So, how do you find the best one?

From material science വരെ installation practices, I’ll walk you through exactly how to choose the right O-ring for high-pressure use.

Which material is best for high-pressure O-rings?

Not all materials survive extreme conditions — some crack, swell, or simply blow out.

എഫ്.കെ.എം., എൻബിആർ, കൂടാതെ ഇപിഡിഎം are your top picks for high-pressure hydraulic applications.

For instance, FKM O-റിംഗ്സ് offer superior heat resistance (up to 200°C), oil compatibility, and pressure retention — making them ideal for industrial hydraulics.

| മെറ്റീരിയൽ | താപനില പരിധി | Fluid Resistance | ഏറ്റവും മികച്ചത് |

|---|---|---|---|

| എഫ്.കെ.എം. | -20°C മുതൽ 200°C വരെ | Excellent (oils, fuels, chemicals) | High-heat, aggressive fluids |

| എൻബിആർ | -40°C മുതൽ 120°C വരെ | Great (mineral oils, water) | പൊതുവായ ഹൈഡ്രോളിക് സംവിധാനങ്ങൾ |

| ഇപിഡിഎം | -50°C മുതൽ 150°C വരെ | Steam, brake fluid | Outdoor, moisture-rich systems |

Want a full breakdown? Check out our FKM vs NBR comparison guide.

What causes O-ring failure in high-pressure systems?

Even the strongest seals fail without proper design and handling.

Cracking, extrusion, and thermal degradation are the top failure modes in high-pressure setups.

From my experience, these three culprits cause 80% of seal failures:

- Underrated material — using a general-purpose O-ring instead of one rated for pressure.

- അനുചിതമായ ഇൻസ്റ്റാളേഷൻ — stretching, twisting, or dry-fitting seals.

- Poor housing design — sharp edges or wrong groove size.

Read more in our O-ring theory guide.

How do you install high-pressure O-rings correctly?

Bad installation kills even the best materials. Here’s how I avoid common mistakes:

- Clean the groove — no dust, no scratches.

- Apply a compatible lubricant.

- Avoid stretching — use the correct size.

- Press evenly — no twisting allowed.

- For custom sizes, try our O-Ring Maker kit.

How often should hydraulic O-rings be replaced?

There’s no one-size-fits-all answer, but here’s what I follow:

- Light duty: inspect every 12 months

- Heavy duty / critical: inspect every 6 months

- Signs of failure: cracks, flat spots, leaks? Replace immediately

Keep a backup O-Ring assortment kit on-site — trust me, it’s worth it.

How to reduce maintenance costs in high-pressure sealing?

Here’s the trick: durability isn't just about strong materials — it’s about preventing wear.

🔧 What works best:

- ഉപയോഗിക്കുക high-temp materials like FKM

- Lubricate every install

- Avoid reusing old O-rings

- Match the groove size to the seal

By doing this, I’ve seen clients cut downtime by 30–40% annually.

തീരുമാനം

High-pressure systems demand O-rings that last — choose the right material, install with care, and inspect regularly.

With smart choices like എഫ്.കെ.എം. അല്ലെങ്കിൽ എൻബിആർ, you’ll avoid breakdowns and extend service life.

Get the Right Seal for Your System

📩 Email:[email protected]

📞 WhatsApp:+86 17622979498

Related post

- FKM vs NBR: Which Oil Seal Material to Choose?

- O-Ring Working Principle Guide

- FKM O-Rings for Heat & Pressure

- Pneumatic Cylinder Seal Selection Guide

- Common Hydraulic Seal Failures