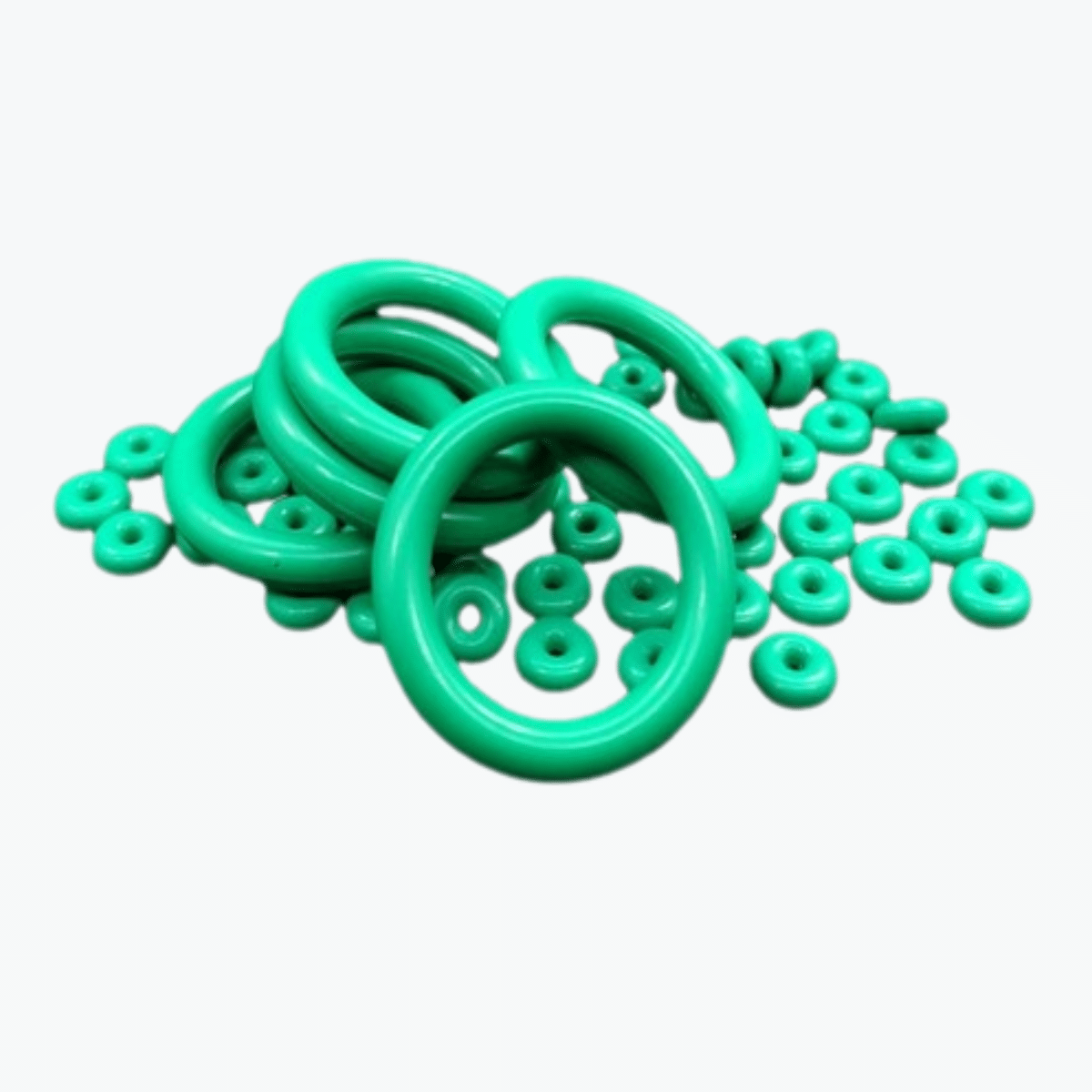

Hydraulic seals often fail under pressure — literally. I’ve learned that selecting the right high-pressure hydraulic O-ring can make or break your system.

When it comes to durability, you need seals that can handle both brutal PSI E aggressive fluids. So, how do you find the best one?

From material science A installation practices, I’ll walk you through exactly how to choose the right O-ring for high-pressure use.

Which material is best for high-pressure O-rings?

Not all materials survive extreme conditions — some crack, swell, or simply blow out.

FKM, NBR, E EPDM are your top picks for high-pressure hydraulic applications.

For instance, Anelli di tenuta FKM offer superior heat resistance (up to 200°C), oil compatibility, and pressure retention — making them ideal for industrial hydraulics.

| Materiale | Intervallo di temperatura | Fluid Resistance | Il migliore per |

|---|---|---|---|

| FKM | -20°C a 200°C | Excellent (oils, fuels, chemicals) | High-heat, aggressive fluids |

| NBR | -40°C a 120°C | Great (mineral oils, water) | Sistemi idraulici generali |

| EPDM | -50°C a 150°C | Steam, brake fluid | Outdoor, moisture-rich systems |

Want a full breakdown? Check out our FKM vs NBR comparison guide.

What causes O-ring failure in high-pressure systems?

Even the strongest seals fail without proper design and handling.

Cracking, extrusion, and thermal degradation are the top failure modes in high-pressure setups.

From my experience, these three culprits cause 80% of seal failures:

- Underrated material — using a general-purpose O-ring instead of one rated for pressure.

- Installazione non corretta — stretching, twisting, or dry-fitting seals.

- Poor housing design — sharp edges or wrong groove size.

Read more in our O-ring theory guide.

How do you install high-pressure O-rings correctly?

Bad installation kills even the best materials. Here’s how I avoid common mistakes:

- Clean the groove — no dust, no scratches.

- Apply a compatible lubricant.

- Avoid stretching — use the correct size.

- Press evenly — no twisting allowed.

- For custom sizes, try our O-Ring Maker kit.

How often should hydraulic O-rings be replaced?

There’s no one-size-fits-all answer, but here’s what I follow:

- Light duty: inspect every 12 months

- Heavy duty / critical: inspect every 6 months

- Signs of failure: cracks, flat spots, leaks? Replace immediately

Keep a backup O-Ring assortment kit on-site — trust me, it’s worth it.

How to reduce maintenance costs in high-pressure sealing?

Here’s the trick: durability isn't just about strong materials — it’s about preventing wear.

🔧 What works best:

- Utilizzo high-temp materials like FKM

- Lubricate every install

- Avoid reusing old O-rings

- Match the groove size to the seal

By doing this, I’ve seen clients cut downtime by 30–40% annually.

Conclusione

High-pressure systems demand O-rings that last — choose the right material, install with care, and inspect regularly.

With smart choices like FKM O NBR, you’ll avoid breakdowns and extend service life.

Get the Right Seal for Your System

📩 Email:[email protected]

📞 WhatsApp:+86 17622979498

Related post

- FKM vs NBR: Which Oil Seal Material to Choose?

- O-Ring Working Principle Guide

- FKM O-Rings for Heat & Pressure

- Pneumatic Cylinder Seal Selection Guide

- Common Hydraulic Seal Failures