I remember the first time I had to deal with a hydraulic leak. It was a frustrating day. The machine was down, production was stalled, and after hours of troubleshooting, I found out the issue was a worn-out hydraulic seal. That was my first lesson in how crucial these small components are.

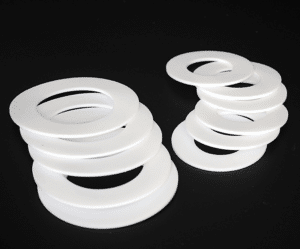

- Hydraulic seals prevent fluid leakage in hydraulic systems, ensuring efficiency and durability. They keep pressure stable and prevent costly downtime.

If you work with hydraulic systems, knowing about seals is non-negotiable. Let’s explore where they are used, how to size them, and how to choose the right one.

Where Are Hydraulic Seals Used?

Hydraulic seals are everywhere—from massive construction equipment to delicate aerospace machinery. If a machine uses hydraulics, it has seals.

- Hydraulic seals are used in construction, automotive, aerospace, and industrial machinery to maintain system efficiency and prevent fluid leaks.

Common Industries Using Hydraulic Seals

| Industry | Common Applications |

|---|---|

| Construction | Excavators, bulldozers, cranes |

| Automotive | Shock absorbers, braking systems |

| Aerospace | Landing gear, flight control systems |

| Manufacturing | Hydraulic presses, molding machines |

How Do You Size Hydraulic Seals?

I’ve seen machines break down just because someone installed the wrong seal size. Precision matters.

- Hydraulic seal sizes depend on shaft diameter, bore diameter, and groove width. Incorrect sizing leads to leaks and inefficiencies.

Sizing Guide for Hydraulic Cylinder Seal Kits

| Seal Type | Inner Diameter (ID) | Outer Diameter (OD) | Groove Width |

|---|---|---|---|

| Rod Seal | Matches shaft diameter | Slightly larger than ID | Fits into rod groove |

| Piston Seal | Matches cylinder bore | Slightly larger than ID | Fits into piston groove |

| Wiper Seal | Matches rod | Matches rod housing | Thin to prevent dust |

What Is the Difference Between Pneumatic and Hydraulic Seals?

Hydraulic and pneumatic seals may look similar, but they serve different functions.

- Hydraulic seals handle high-pressure liquids, while pneumatic seals are designed for lower-pressure air or gas systems.

Comparison of Hydraulic and Pneumatic Seals

| Feature | Hydraulic Seals | Pneumatic Seals |

|---|---|---|

| Medium | Liquid (oil, water) | Gas (air, nitrogen) |

| Pressure Resistance | Up to 10,000 psi | Up to 300 psi |

| Common Material | NBR, FKM, PTFE | Polyurethane, NBR |

| Applications | Heavy equipment, industry | Compressors, pneumatic tools |

How to Choose the Right Hydraulic Seal?

Finding the right seal isn’t just about size—it’s about performance in real-world conditions.

- Choose based on seal type, temperature, pressure, and material compatibility.

Key Factors When Choosing Hydraulic Seals

- Seal Type – Rod, piston, wiper, rotary, each serves a specific purpose.

- Material – NBR, FKM, PTFE, TPU all have unique chemical and heat resistance.

- Temperature Range – Your seal must endure the operating conditions.

- Pressure Rating – Match seal durability with your system’s PSI range.

- Fluid Compatibility – Ensure your seal material won't degrade.

Explore our hydraulic seal kits by size for an easy fit.

How to Replace Hydraulic Seals?

Replacing a hydraulic seal is not rocket science—but it does require attention to detail.

- Depressurize the System – Safety first.

- Disassemble the Cylinder – Access rod/piston components.

- Remove Old Seals – Avoid scratching the grooves.

- Install New Seals – Use proper tools, avoid over-stretching.

- Reassemble & Test – Check for leaks under pressure.

Need guidance? Check out our hydraulic seal measurement guide.

Get the Right Seals for Your Equipment

Need help choosing or replacing hydraulic seals?

Email us at [email protected] or message us on

WhatsApp: +86 17622979498 for fast assistance.