| Hydraulic Seal Type | Material | Estimated Price (Per Unit in USD) |

|---|---|---|

| Rod Seals (DHS, IDU, UHS) | PU, NBR, FKM | $0.50 - $5.00 |

| Piston Seals (OK, ODU, KDAS) | PU, NBR, PTFE | $1.00 - $8.00 |

| Wiper Seals (FA Dust, USH) | PU, NBR | $0.30 - $3.00 |

| Rotary Seals (STD Rotary Glyd, STD Shaft Seal) | PTFE, NBR, FKM | $2.00 - $10.00 |

| Guide Rings (Guide Band) | PTFE, Composite | $0.80 - $6.00 |

| Compact Seals (V Compact, KDAS) | PU, NBR, Fabric | $3.00 - $12.00 |

| High-Pressure Hydraulic Seals (LBH, UPH) | NBR, FKM, PTFE | $5.00 - $15.00 |

| Custom Hydraulic Seals | Based on requirements | Contact us for a quote |

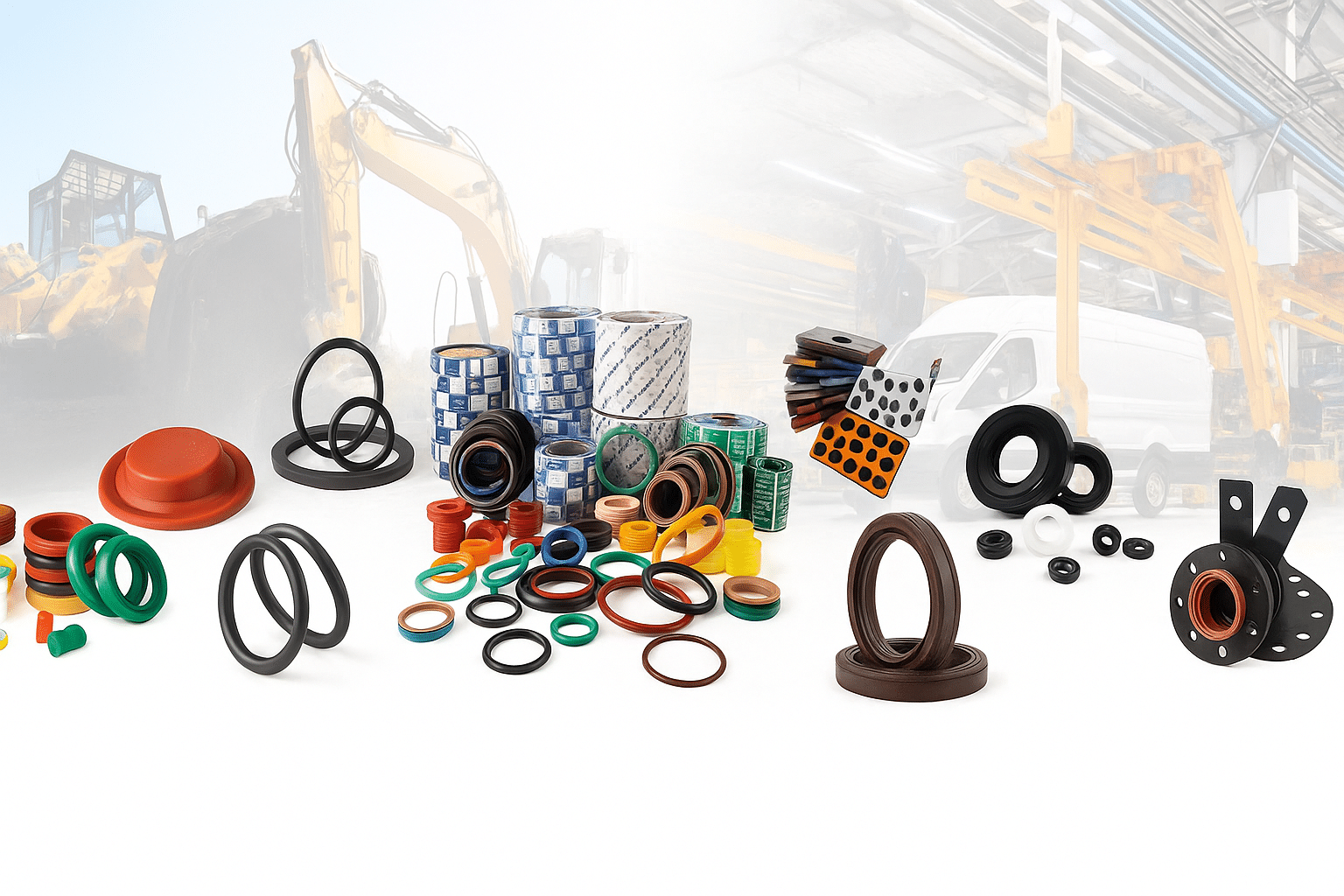

HYDRAULIC SEAL MANUFACTURER

About

We’re committed to helping clients lower sourcing costs and increase product sales. Today, over 95% of our customers come back to reorder. You can start your inquiry from just 1 PC — no MOQ required.

We provide

- 0 MOQ

- 3 Days Delivery

- Over 95% of buyers choose to reorder with us

- Factory Direct Price

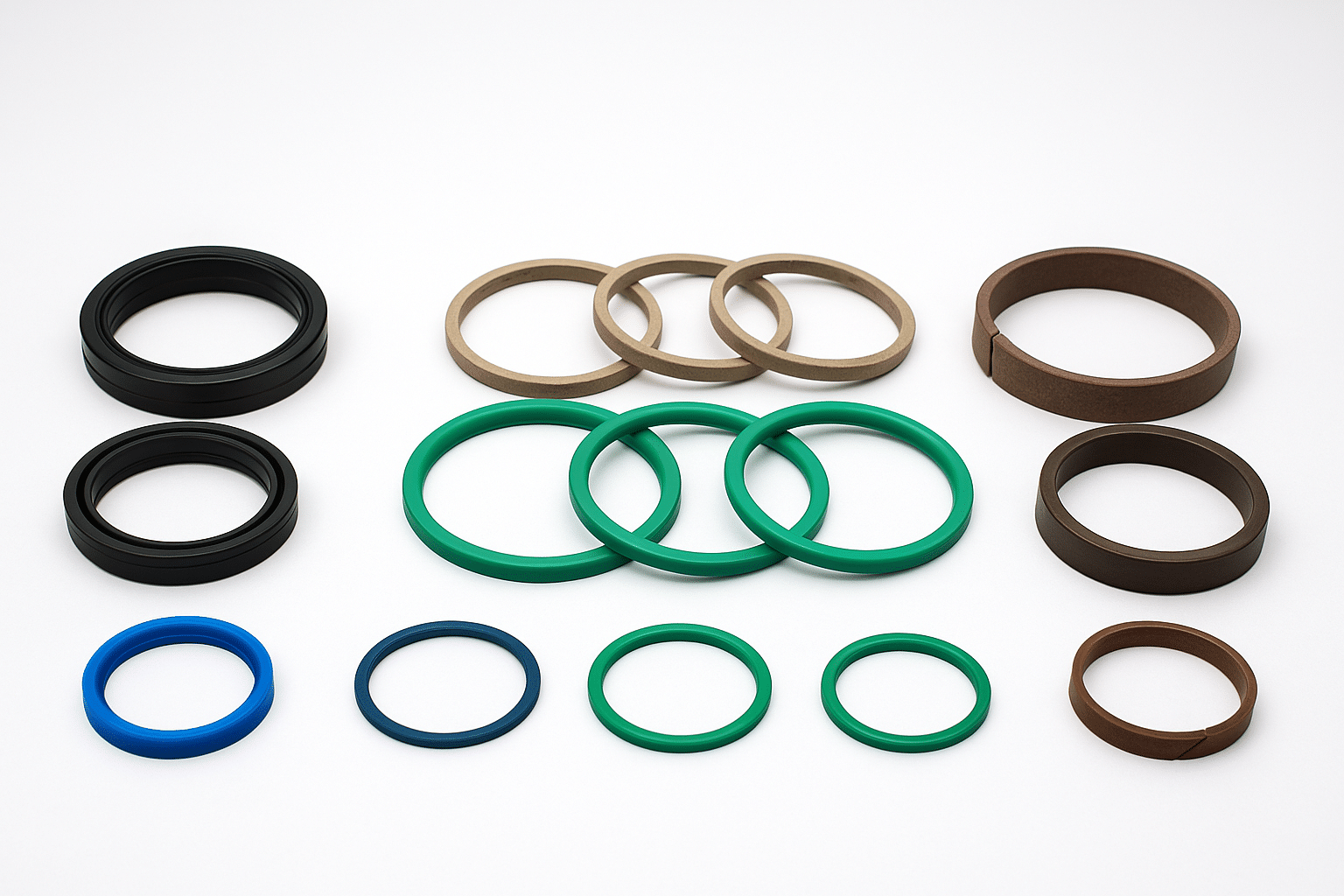

Hydraulic Seal Types

Get Your Custom Quote Instantly

Send your inquiry now – from just 1 PC.

We’ll get back to you within 2 hours!

SPRING SALE!

Factory Direct. Global Ready

HYDRAULIC SEAL MANUFACTURER

OEM-grade seals, flexible MOQ, and 100% material traceability.

Why choose Hengoseal as your HYDRAULIC SEAL supplier

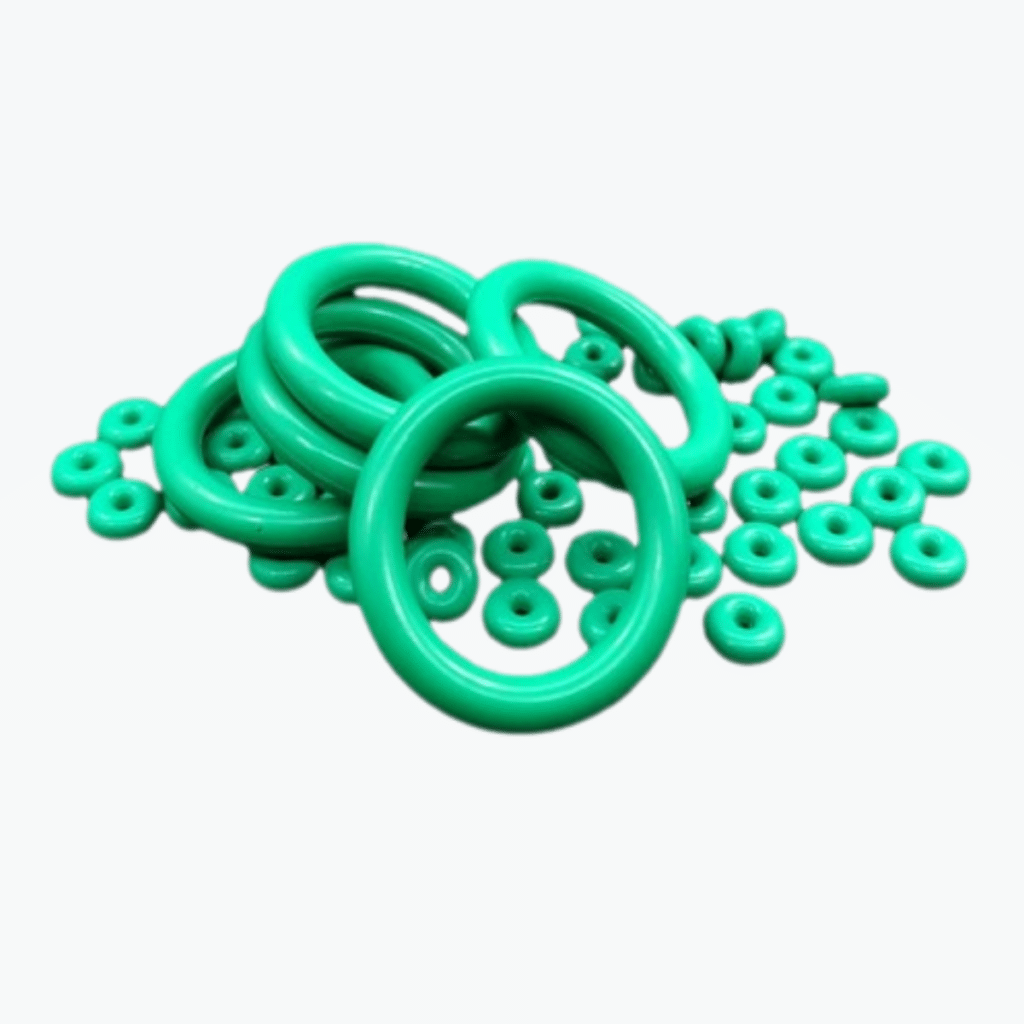

Thousands of O-Ring sizes in stock. Most standard items ship within 72 hours. No delays, no headaches.

More than 95% of our clients reorder — thanks to consistent quality, reliable delivery, and responsive service.

Work directly with the manufacturer. No trading margin. No middleman. Competitive price guaranteed.

From NBR to FDA-grade Silicone and FKM, we offer the right compound for every sealing application.

Fast handling. Most orders are dispatched within 3 working days, with urgent delivery available.

Order from 1 piece. Perfect for prototyping, urgent repair, or low-volume needs.

Hydraulic Seals Size Chart

| Hydraulic Seal Type | Material | Inner Diameter (mm) | Outer Diameter (mm) | Thickness (mm) | Application |

|---|---|---|---|---|---|

| DHS Hydraulic Seals | PU, NBR | 10 to 300 | 20 to 450 | 5 to 15 | Rod and piston sealing in hydraulic cylinders |

| FA Dust Seal | PU, NBR | 15 to 280 | 30 to 500 | 4 to 12 | Prevents dust and contaminants from entering hydraulic systems |

| Guide Band | PTFE, Composite | 12 to 250 | 25 to 420 | 3 to 10 | Reduces friction and improves piston/rod guidance |

| IDU Hydraulic Seals | PU, NBR, FKM | 20 to 350 | 40 to 550 | 5 to 14 | High-pressure leak prevention |

| J Hydraulic Seals | PU, PTFE, NBR | 18 to 320 | 35 to 500 | 6 to 18 | Used in dynamic and static hydraulic applications |

| KDAS Compact Seal | PU, NBR, Fabric | 25 to 380 | 45 to 600 | 7 to 20 | Heavy-duty piston sealing |

| LBH Hydraulic Seals | NBR, FKM, PTFE | 30 to 400 | 50 to 650 | 6 to 22 | Wear-resistant sealing for hydraulic applications |

| STD Rotary Glyd Ring | PTFE, NBR | 15 to 250 | 30 to 480 | 3 to 12 | Low-friction rotary sealing |

| STD Rotary Shaft Seal | NBR, FKM, PU | 20 to 350 | 40 to 550 | 5 to 15 | Rotary shaft leakage prevention |

| V Compact Seal | PU, PTFE, Fabric | 25 to 320 | 45 to 500 | 5 to 14 | Space-saving piston sealing solution |

Estimated Hydraulic Seal Price

Hydraulic Seals

Estimated Manufacturing and Shipping Times

Our streamlined process guarantees quick turnaround times while maintaining superior sealing performance for all applications.

Manufacturing Time

1-5 business days (depending on order volume).

Custom Orders

Delivery time can be 5-10 business days for highly customized products.

Shipping Time

Typically 7-14 days for international orders, depending on your location.

Our promise

We are committed to providing quick and reliable service, ensuring your Hydraulic Seals are delivered in the shortest time possible without compromising on quality.

The Whole Process of Hydraulic Seals Production

We work efficiently to deliver high-quality Hydraulic Seals on time. Here’s a breakdown of the whole production process:

Design and Manufacturing Time

We manufacture hydraulic seals based on customer specifications using high-quality materials such as NBR, FKM, PU, and PTFE. Our precision molding and machining ensure excellent sealing performance and durability.

Quality Control and Testing

Every batch of hydraulic seals undergoes strict quality control testing, ensuring leak-proof performance, chemical resistance, and high-pressure stability. Our products meet industry standards for hydraulic applications.

Packaging and Shipping

Once production is complete, the hydraulic seals are securely packaged to prevent damage during transportation. We offer fast global shipping, ensuring timely delivery.

Customization and Adjustments

For custom orders, we tailor the size, material, and design of hydraulic seals to meet specific industrial needs, ensuring compatibility with various hydraulic and pneumatic systems.

Hydraulic Seals Selection, Maintenance, and Cost Tips

Hydraulic seal you need to know

1. What is a hydraulic seal?

A hydraulic seal is a soft, non-metallic ring used to block fluid leakage in hydraulic systems. It maintains pressure and prevents contamination between different parts in a hydraulic cylinder or piston.

2. What is a hydraulic seal used for?

Hydraulic seals are used to contain hydraulic fluid, maintain pressure, and prevent leaks in equipment like cylinders, pumps, and valves. They ensure smooth, reliable motion in high-pressure systems.

3. How to replace hydraulic cylinder seals?

To replace hydraulic cylinder seals, first remove the cylinder from the machine, disassemble the components, take out old seals, clean the parts, install new seals in the correct grooves, and reassemble the cylinder.

4. Where to buy hydraulic seals?

You can buy hydraulic seals directly from specialized manufacturers like Hengoseal.com, which offers various types including rod seals, piston seals, and seal kits with no minimum order quantity.

5. How to install seals in a hydraulic cylinder?

To install seals in a hydraulic cylinder, carefully stretch or slide the seals into their designated grooves using seal installation tools. Avoid damaging the lips, and lubricate the seals before reassembly.

6. How to measure a hydraulic cylinder for seals?

To measure a hydraulic cylinder for seals, determine the rod diameter, bore diameter, groove width, and depth using a caliper. Precise dimensions are critical for selecting the correct seal size and type.