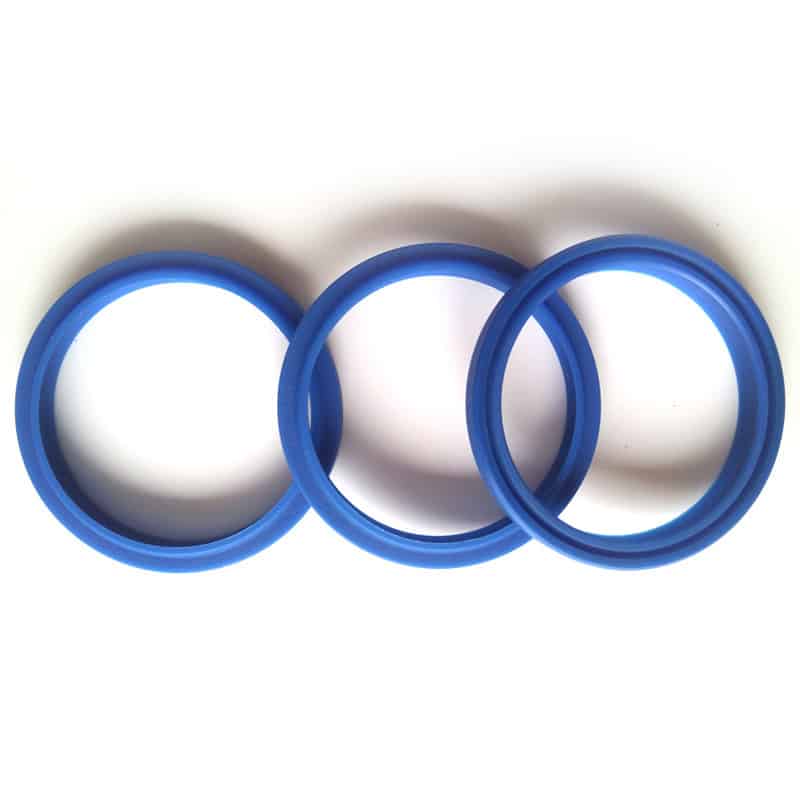

Ever opened a bag of seals only to find them brittle, dusty, or warped? I’ve had seals crack before installation—just because they were stored wrong. It’s a silent killer for performance and reliability.

To store hydraulic seals properly, keep them in a cool, dry, and dark place, avoid direct sunlight, extreme heat, or humidity, and never hang or stretch them. Proper handling prevents deformation, contamination, and premature aging.

Whether you're a distributor or just keeping spares, learning to store and handle seals correctly can extend their lifespan and prevent costly failures.

Why does storing hydraulic seals the right way matter?

Hydraulic seals are made from materials like NBR, FKM, PTFE, and PU—all of which are sensitive to:

- UV light – breaks down rubber molecules

- Ozone exposure – causes surface cracking

- Heat & humidity – accelerate aging

- Improper handling – causes deformation and flattening

I once shipped a batch of seals to a client who stored them near a window in midsummer. A month later, he called about 20% of them cracking. It wasn’t a material issue—it was sunlight exposure.

What are the best practices for storing hydraulic seals?

Here’s what I recommend and personally follow in our warehouse:

- Temperature: Keep between 10°C and 25°C

- Humidity: Below 65% RH

- Light: Store in opaque bags or boxes, away from UV sources

- Position: Flat and unstressed—not hung, twisted, or under weight

- Shelf: Use drawers, trays, or seal cabinets—not plastic hooks

| Storage Factor | Recommended Practice |

|---|---|

| Temperature | 10–25°C stable room temp |

| Humidity | < 65% RH |

| Light | Avoid sunlight and UV |

| Packaging | Original sealed bags or paper boxes |

| Positioning | Lay flat, no pressure or tension |

We provide ziplock-sealed, moisture-proof packaging for all exported seals. Want your brand on the bag? Let us know.

How long can you store hydraulic seals without quality loss?

Shelf life depends on the material:

| Material | Shelf Life (unopened) |

|---|---|

| NBR | 5–7 years |

| FKM | 10+ years |

| PU | 3–5 years |

| PTFE | 10+ years |

General best practices include:

- Use First In, First Out (FIFO) rotation

- For critical applications, install within 2–3 years

- Avoid stockpiling in uncontrolled environments

I label every incoming batch with a date and rotate monthly in our export warehouse to ensure consistent quality.

How should you handle hydraulic seals before installation?

Even the best-stored seal can be ruined by poor handling.

Best handling tips:

- Wash hands or wear gloves to prevent oil transfer

- Never stretch or fold seals

- Use soft-edge tools for installation

- Inspect lips and surfaces for cracks or stickiness

- Reseal unused parts in airtight packaging

If you’re working with a UN Rod Seal or KDAS Buffer Seal, always check the sealing lips and tension rings before mounting.

Can you store hydraulic seals long-term for resale or distribution?

Absolutely. Many of our distributors store hydraulic seal kits and individual parts for 2–3 years or more without performance loss—if sealed and stored correctly.

We support this by:

- Including production and expiration dates

- Using zip-seal bags with silica gel

- Offering custom packaging and labeling with your logo

For distributors handling large SKU assortments, we can separate kits by cylinder size to streamline shelf organization.

Conclusion

A seal is only as good as how it’s stored. Keep them sealed, flat, cool, and clean to ensure top performance—whether you install one or sell thousands.

Ensure your seals last with the right packaging

Want storage-friendly packaging or warehouse-ready labeling?

📧 Email: [email protected]

📱 WhatsApp: +86 17622979498

We customize bagging and barcoding for your team and your shelves.

Related topic

Hydraulic Seal Storage & Handling Guide

How to Measure Hydraulic Seals for Perfect Replacement

Common Hydraulic Seal Failures and How to Prevent Them