Sealing just one part of your hydraulic cylinder isn’t enough. To prevent leakage, absorb shocks, and reduce downtime—you need a complete seal stack.

A hydraulic seal stack is a strategic combination of rod, piston, buffer, and wiper seals. When built correctly, it ensures your system performs under pressure, lasts longer, and leaks less.

In this 2025 guide, I’ll walk you through how to build the perfect seal stack for your hydraulic cylinders.

What is a hydraulic seal stack?

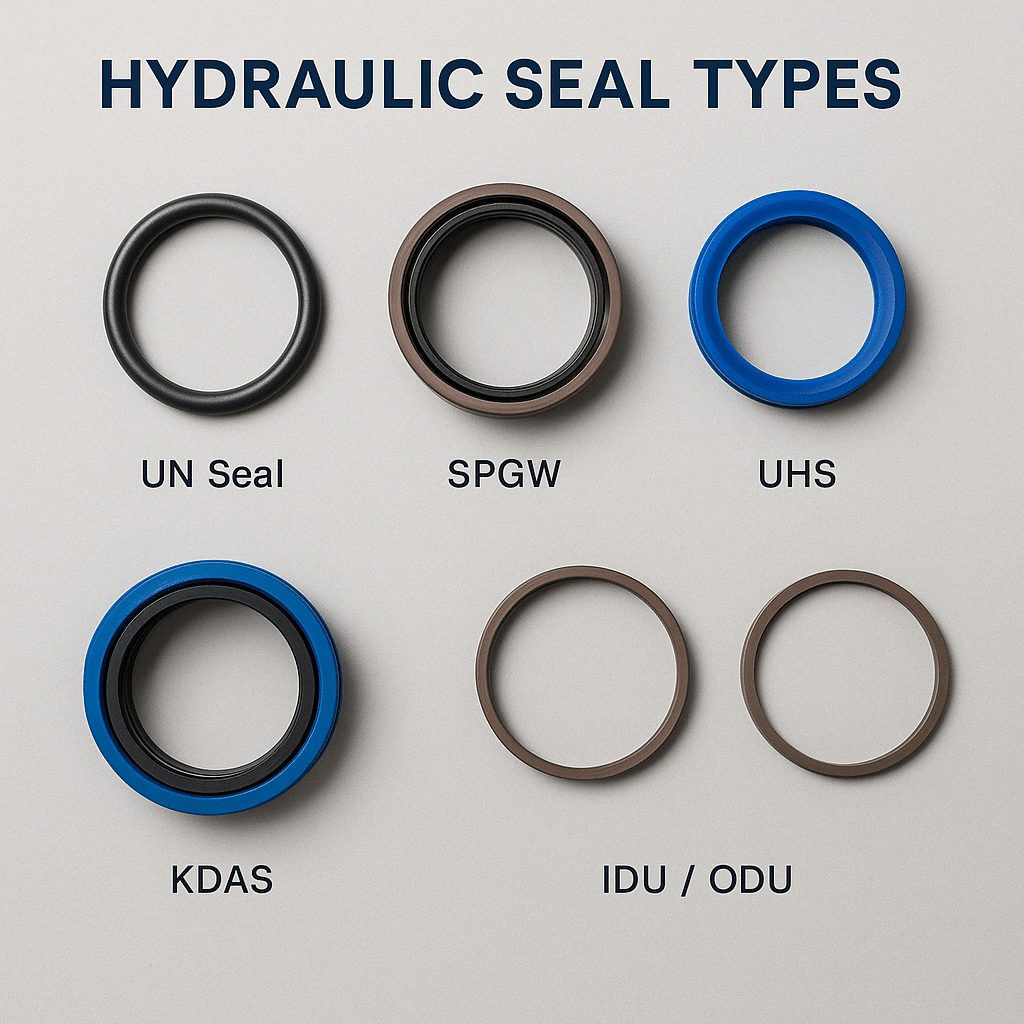

A seal stack is a layered arrangement of different seal types in one cylinder—each handling a specific role:

- Rod seals to block fluid from exiting

- Piston seals to divide pressure chambers

- Buffer seals to absorb shocks and prevent extrusion

- Wipers to keep contaminants out

- Guide rings to ensure alignment and prevent side loading

At Hengoseal, we often combine UN rod seals, IDU/ODU piston seals, and KDAS buffer seals in a single cylinder for optimal sealing.

Which seals should be included in a standard cylinder?

Here’s a typical seal stack layout for a double-acting hydraulic cylinder:

| Position | Seal Type | Example Product |

|---|---|---|

| Rod Side | Rod Seal | UN Hydraulic Seal |

| Rod Side | Buffer Seal | KDAS Compact Seal or UHS |

| Rod Side | Wiper Seal | Custom Dust Seal |

| Piston Side | Piston Seal | IDU/ODU Seal |

| Guide | Wear Ring | FA or PTFE Guide Band |

Depending on the application, you can swap KDAS for V-type seals or use USH buffer seals for higher extrusion resistance.

How do you choose seals based on pressure and stroke?

| Condition | Recommended Seals |

|---|---|

| Pressure ≤ 25 MPa | UN + IDU + UHS |

| Pressure 25–40 MPa | UN + KDAS + ODU |

| Pressure ≥ 40 MPa | V-type seal + USH buffer |

| Stroke ≤ 100mm | IDU + KDAS |

| Stroke ≥ 300mm | ODU + USH + reinforced wiper |

If your application involves sudden pressure spikes or long-stroke movement, you’ll need additional buffer or guide elements to prevent seal blowout and misalignment.

Need help measuring your groove? Visit our guide on how to measure hydraulic seals accurately.

What materials should you use in a seal stack?

Choosing the right material ensures your seal stack resists wear, heat, and chemical damage.

| Material | Use Case |

|---|---|

| NBR | Mineral oil systems, -30~100°C |

| FKM | High-temp or fuel systems, up to 200°C |

| PU | Abrasion-resistant, long-stroke systems |

| PTFE | Chemical resistance, low friction |

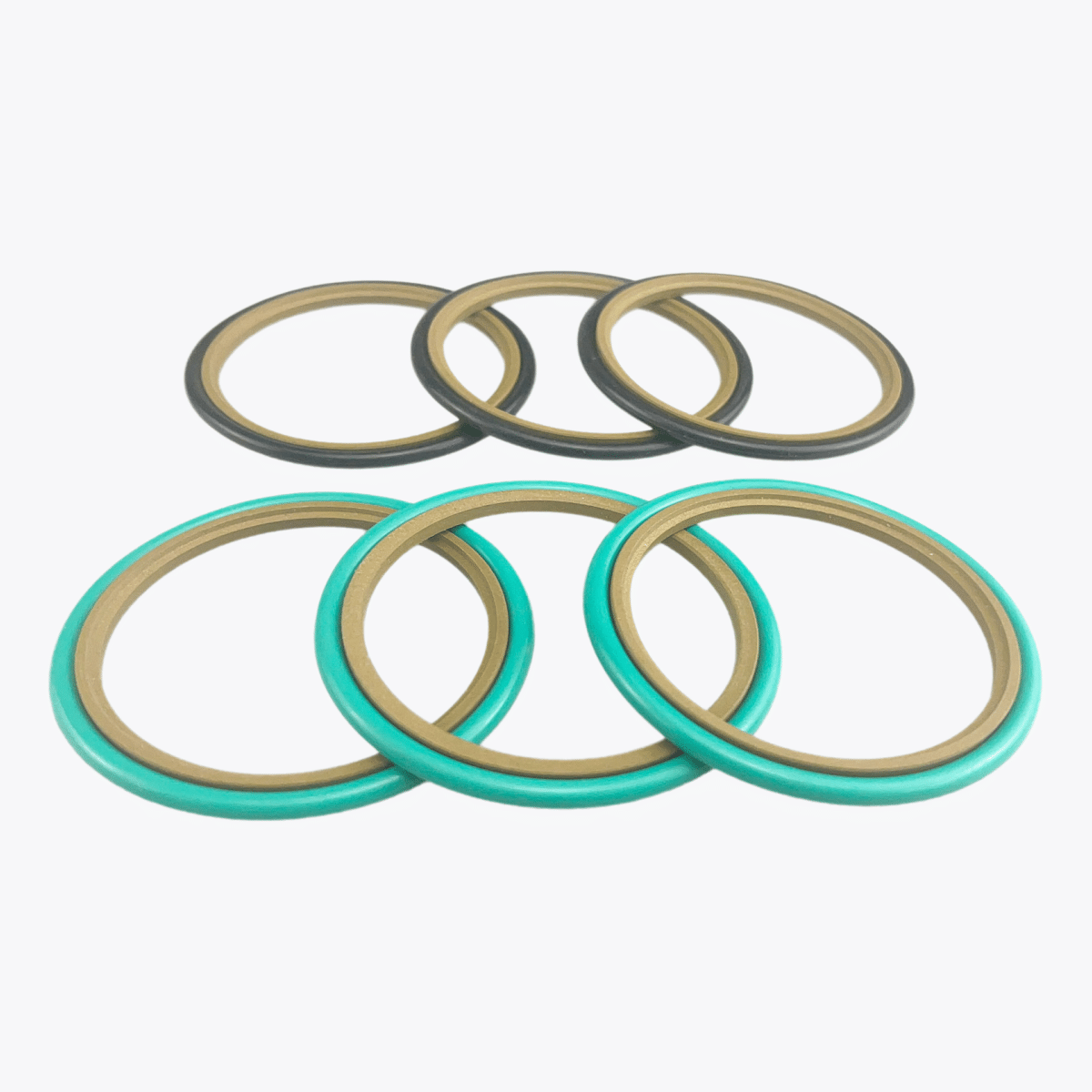

You can combine materials—such as a PTFE piston seal with a PU buffer and FKM rod seal—for optimal performance in multi-fluid systems.

What are the most common sealing failures—and how to avoid them?

- Leakage – Caused by undersized seals or incorrect groove.

- Extrusion – Happens under high pressure without buffer rings.

- Wear – From side loading or dry friction.

- Contamination – When no wiper seal is used.

To avoid these, follow our seal failure prevention guide and always use a complete stack.

Conclusion

A well-designed hydraulic seal stack is the foundation of a leak-free, high-performance cylinder. Pair the right seal types, materials, and dimensions—and your system will thank you.

Get your custom seal stack designed today

📩 mail:[email protected]

📞 WhatsApp:+86 17622979498

Related topic

- KDAS Hydraulic Seals: Which Buffer Seal Is Best?

- UN Hydraulic Seal Guide

- IDU vs ODU Piston Seals Comparison

- V-Type Seals for Extreme Pressure

- UHS vs USH Seal Comparison