Ordering the wrong seal size can delay your repair, cost you money, and worst of all—leave your machine down for days. I’ve made that mistake, and I don’t want you to.

To measure a hydraulic seal correctly, you need to record the inner diameter (ID), outer diameter (OD), and cross-section width. These dimensions must match the cylinder's groove to ensure a proper fit.

Let me walk you through how I measure seals in my daily work—and how you can avoid common errors, even without fancy equipment.

What tools do I need to measure a hydraulic seal accurately?

Without the right tools, seal measurement turns into guesswork. And guesswork leads to leaks.

In my toolbox, I always keep:

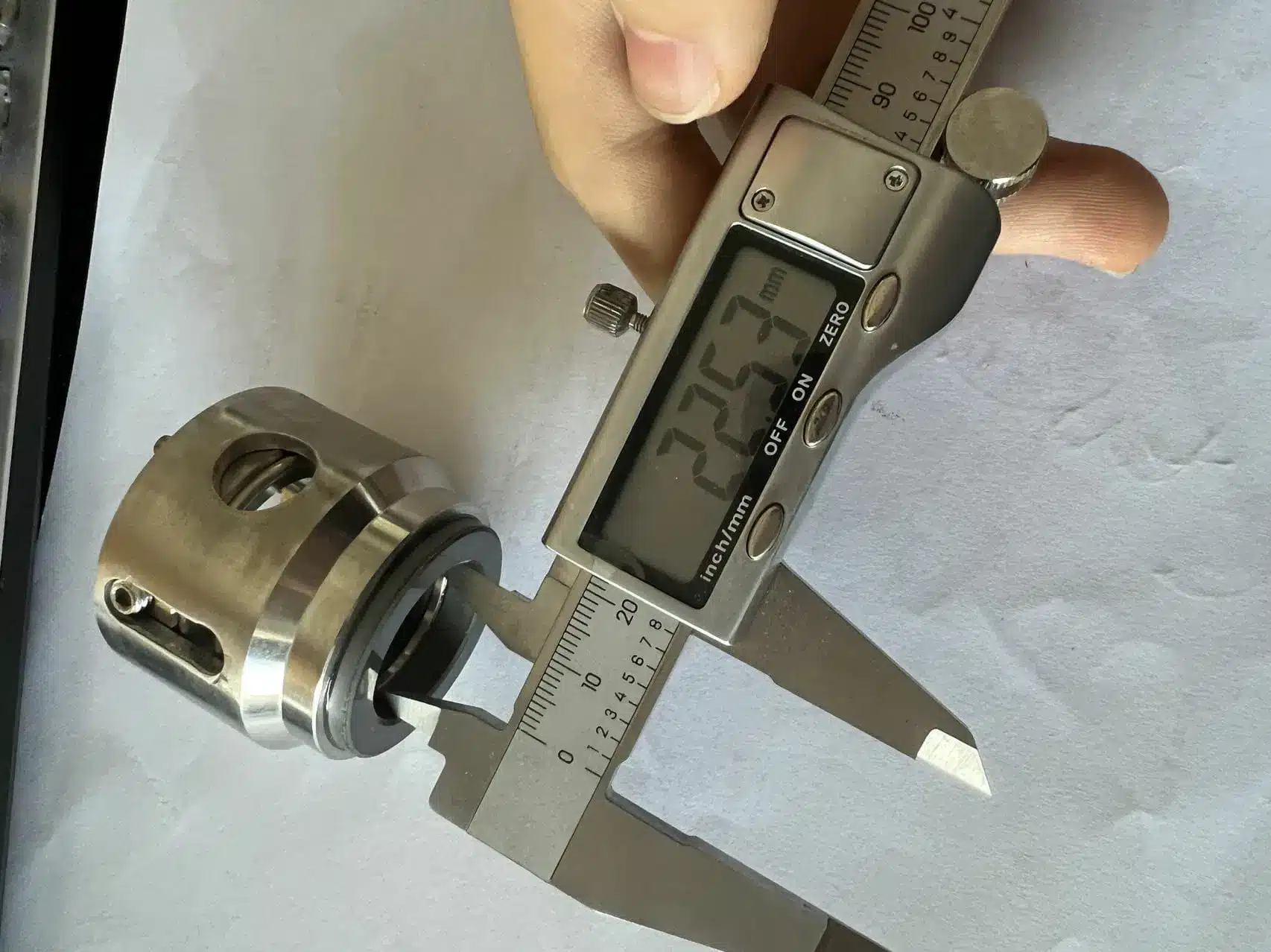

- Digital caliper (0.01 mm accuracy)

- Flat surface or steel plate

- Clean cloth for oil removal

- Backup: vernier caliper

- Notepad or printable measurement form

These tools help me measure every seal—whether it’s brand new or worn beyond recognition.

| Tool | Purpose |

|---|---|

| Digital Caliper | ID, OD, and width measurement |

| Flat Plate | Ensures seal lies flat for accuracy |

| Cloth | Wipe away residue before measuring |

| Seal Form | Record specs for matching and quote |

If you're working with standard sizes, check out our hydraulic seal kits by size to simplify reordering.

How do I measure a worn or damaged hydraulic seal?

Measuring worn seals is tricky, but not impossible. The key is cleaning and consistency.

Here’s my step-by-step:

- Wipe the seal with alcohol and cloth

- Lay it flat on a smooth surface

- Measure ID, OD, and width three times from different points

If the seal has lost shape, I average the numbers. Recently I matched a distorted seal at 45x56x7 mm—perfectly aligned with our UN Hydraulic Seal line.

For damaged or incomplete samples, take a clear photo with a ruler next to it and send it to us—we’ll identify the closest match fast.

Can I measure directly from the cylinder groove?

Yes—and it’s often more accurate if the old seal is missing or destroyed.

Here’s how I do it:

- Measure groove width to match seal width

- Measure groove ID or OD (depending on rod or piston side)

- Optionally, check groove depth for compatibility with single/double-lip seals

| Groove Feature | Measurement Tool | Seal Correspondence |

|---|---|---|

| Width | Digital Caliper | Seal Width |

| Diameter | ID/OD Gauges | Rod or Piston Match |

| Depth | Depth Micrometer | Lip Fit, Seal Retention |

Need a sizing guide for grooves? Contact us by whatsapp or mail.

What if I can’t identify the seal type?

Don’t worry—it happens to most professionals at some point.

Here’s what to send us:

- Clear photos of the seal (front, side, installed)

- Machine brand and model info

- All three dimensions: ID, OD, and width

- Optional: drawing or part number

We’ve matched thousands of seals for everything from forklift cylinders in Chile to mining machinery in Kazakhstan. Often, it's just about matching profiles like KDAS, IDU, or UN.

If you're running a service team, ask us about our printable spec sheet for field techs.

How to choose the correct hydraulic seal size?

Use this checklist:

- Clean the seal completely before measuring

- Record all three dimensions: ID, OD, width

- When in doubt, measure the groove—not the seal

- If old seal is distorted, average the numbers

- Send a photo with a scale or ruler for verification

Once you’ve got the specs, match with our hydraulic seal product range or send it to us for confirmation.

Conclusion

The right seal starts with the right measurement. A few millimeters can make or break your system. Use accurate tools, follow a step-by-step approach, and lean on suppliers like us when you're unsure.

Ready to get it right?

Need help measuring or matching a hydraulic seal?

📧 Email: [email protected]

📱 WhatsApp: +86 17622979498

We respond fast—and support matches via photo, sample, or drawing.

Related topic

UN Hydraulic Seal

How to Choose Hydraulic Seal Kits by Size

Hydraulic Seal Kit by Size