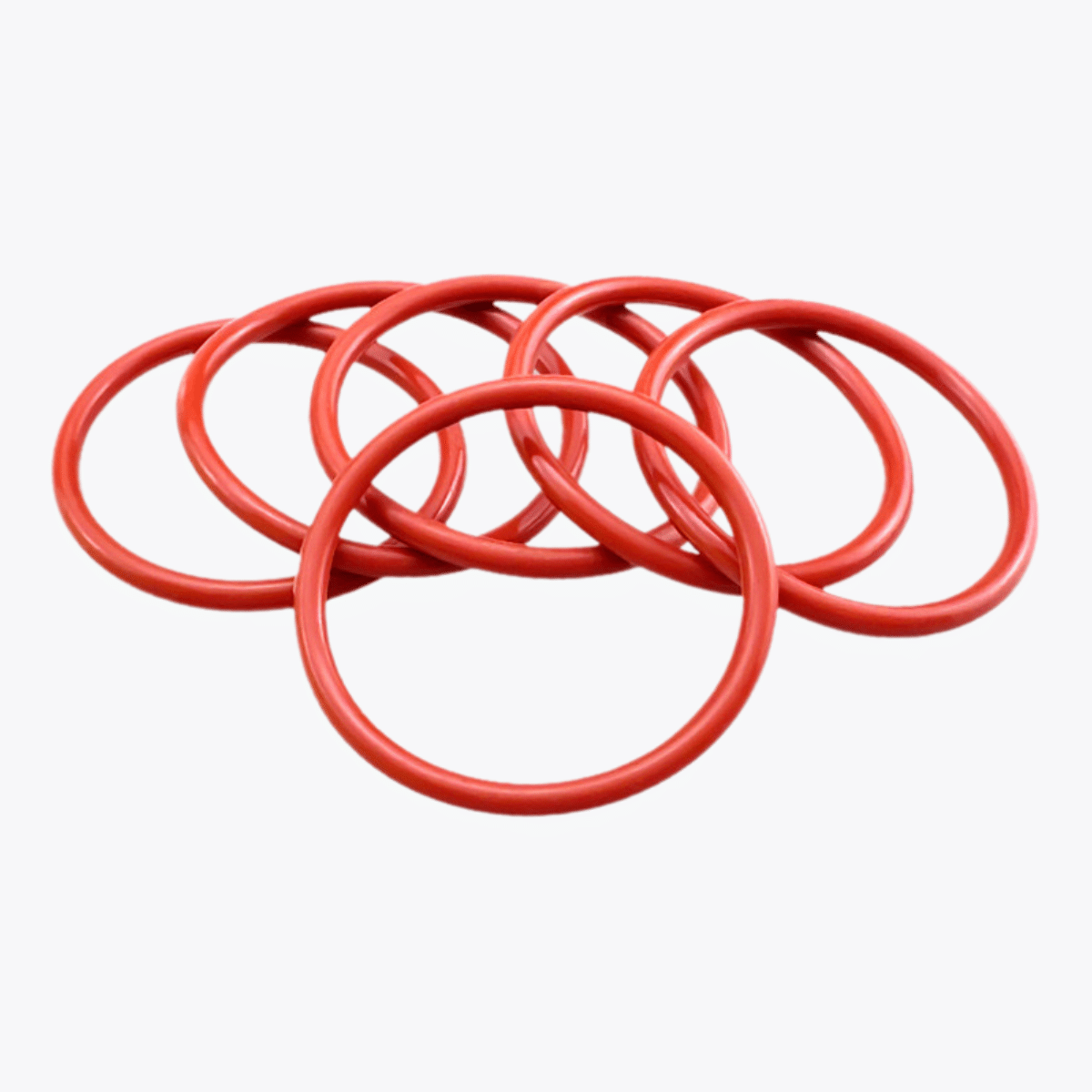

Silicone O-Ring – Flexible, Food-Safe & Heat-Resistant Seals

- 0 MOQ

- 3 DAYS DELIVERY

- 100% customer repurchase rate

Send your inquiry now !

Silicone O-Ring – Flexible, Food-Safe & Heat-Resistant Seals

Silicone O-Rings are the perfect choice for applications requiring flexibility, high temperature resistance, and food safety compliance. Qu'il soit utilisé dans food processing equipment, medical devices, or high-heat sealing environments, they deliver consistent performance and durability.

Product Details

| Matériel | Silicone Rubber (VMQ – Vinyl Methyl Silicone) |

|---|---|

| Hardness | 40–80 Shore A |

| Plage de température | -60°C to +230°C (special grades up to +250°C) |

| Couleur | Red, white, transparent, black, custom colors available |

| Résistance chimique | Excellent resistance to weather, ozone, steam, and many chemicals; good dielectric properties |

| Limites | Not recommended for petroleum oils, fuels, or concentrated acids |

Why Choose Silicone O-Rings?

Silicone O-Rings (also known as silicone rubber O-rings, heat-resistant seal rings, ou FDA silicone O-rings) offer excellent resilience, flexibility, and resistance to extreme temperatures ranging from -60°C to +230°C. They maintain sealing integrity in both low-temperature freezing conditions et high-heat operations.

Caractéristiques principales

-

Wide Temperature Range: Operates from -60°C to +230°C, suitable for extreme environments.

-

Food & Medical Grade Options: Disponible en FDA-approved et platinum-cured silicone for hygienic applications.

-

Excellent Flexibility: Maintains elasticity even after long-term use.

-

Non-Toxic & Odorless: Safe for food, beverage, and medical sealing applications.

-

Color Options: Disponible en red, white, transparent, and custom colors for industry-specific needs.

Applications

Silicone O-Rings are widely used in:

-

Transformation des aliments et des boissons (blenders, coffee machines, dairy equipment)

-

Medical & Pharmaceutical Equipment (pumps, sterilization systems, diagnostic devices)

-

Scellage à haute température (baking ovens, heating elements, industrial dryers)

-

Electronics & Lighting (waterproof seals for LED lights and electrical housings)

-

Water Filtration Systems

Material Comparison – Silicone vs Other O-Ring Materials

| Matériel | Temp Range (°C) | Food Grade | Résistance à l'huile | Flexibilité | Cost Level |

|---|---|---|---|---|---|

| Silicone | -60 to +230 | Yes (FDA) | Équitable | Excellent | Moyen |

| NBR (Buna-N) | -40 to +100 | No* | Excellent | Bien | Faible |

| FKM (Viton) | -20 to +200 | No* | Excellent | Bien | Haut |

| EPDM | -50 to +150 | Yes (FDA) | Équitable | Bien | Moyen |

* Special grades available for food applications.

Related O-Ring Products

-

O-Ring Collection Page – O-Ring Manufacturer

-

Guide: Guide des joints toriques

-

Related Product: Joint torique en EPDM

-

Related Product: Joint torique FKM

FAQ

Q1: Can Silicone O-Rings be used for hot water sealing?

Yes, silicone performs well in hot water, making it ideal for beverage machines and steam systems.

Q2: Are silicone O-Rings safe for food contact?

Oui, FDA-approved silicone O-rings are safe for direct food and beverage contact.

Q3: How does silicone compare to Viton in high temperatures?

Silicone can handle slightly higher temperatures but offers lower chemical resistance than Viton.

Q4: Are silicone O-Rings suitable for oil sealing?

Silicone is not recommended for heavy oil contact; NBR or Viton would be better.

Q5: Can silicone O-Rings be used in freezing conditions?

Yes, silicone remains flexible and sealing-capable down to -60°C.

Your Trusted Silicone O-Ring Supplier

À Hengoséal, we supply custom and standard silicone O-rings to industries worldwide, ensuring consistent quality, quick delivery, and competitive prices. Que vous ayez besoin FDA-grade, high-temperature, or custom-colored O-rings, we can meet your needs with no MOQ.

📩 Courriel : [email protected] | 📞 WhatsApp: +86 17622979498