Sourcing the wrong gasket seal manufacturer can mean late deliveries, leaking products, or worse—losing your customers’ trust.

If you're in the business of machinery, automotive, or fluid systems, finding a supplier who delivers consistent quality, supports custom specs, and ships on time is essential to staying competitive. Let's break down what makes a gasket seal manufacturer truly reliable—and why many global buyers are turning to Hengoseal.

When it comes to gasket seals, not all manufacturers are created equal. This article dives deep into product types, industry applications, delivery capacity, real customer stories, and what makes one supplier stand out from the rest.

What types of gasket seals should a professional manufacturer offer?

A reliable manufacturer doesn’t just sell one kind of seal—they provide an entire portfolio to meet diverse applications.

At minimum, a full-range gasket seal supplier should cover:

- O-ringoj: Versatile sealing rings for hydraulic, pneumatic, and automotive systems. Available in NBR, FKM, silicone, EPDM, and more. Visit the O-Ring seal section to explore different material and size configurations.

- Gaskets & Retaining Rings: Ideal for static sealing in flanges and pipe connections.

- Automotive Oil Seals: Designed for shafts, crankcases, wheels, and gearboxes. See common use cases in the automotive oil seal guide.

- Rotary Shaft Seals: Engineered for high-speed rotary motion. Includes single/double lip TC seals and reinforced designs.

- Hidraŭlikaj Sigeloj: Piston, rod, buffer, and wear rings to prevent internal leakage in cylinders.

- Starter Motor Seals: Durable options for intense thermal and mechanical cycling.

A vendor who controls their mold design, material sourcing, and can scale volume quickly is best positioned to support your evolving needs.

Which industries benefit most from custom gasket seal manufacturing?

An experienced gasket seal factory serves a wide range of industries—not just one.

-

Automotive OEMs and Aftermarket Distributors

From passenger cars to heavy-duty fleets, oil seals and gaskets must meet tight tolerances and resist heat, oil, and vibration. Hengoseal’s Toyota Oil Seal line is a popular choice in Asia and Africa. -

Industrial Hydraulic Equipment

Piston and rod seals in excavators, presses, and pumps are key to zero leakage. Our Hidraŭlika Sigelo options cover IDU/ODU, UN, KDAS, and more. -

Pneumatic Cylinder Systems

Buffer seals, dust wipers, and cushion rings help reduce wear and increase system lifespan. Explore use cases in our Pneumatic Seals Guide. -

Maintenance & Repair Operators (MRO)

Having assorted kits like our Sortimento de O-ringoj helps repair shops reduce downtime and serve diverse models. -

Agricultural & Construction Machinery

Equipment in outdoor, high-dust, or muddy conditions requires robust sealing with materials like PTFE or FKM. The KDAS Kompakta Sigelo is frequently used in loaders and diggers.

How Hengoseal helped global buyers solve sealing problems faster and better

Here are real-world examples of how Hengoseal supports buyers in diverse markets.

“We switched to Hengoseal after delays from our old vendor. They got us fully customized piston seals in under three weeks—and kept the quality consistent.”

— 🇨🇦 Project Manager, Hydraulic Equipment OEM“We saved over 30% on gasket seals without compromising on quality. Their MOQ policy is ideal for growing businesses like ours.”

— 🇩🇪 Procurement Lead, Automotive Parts Distributor

🇬🇧 UK Hydraulic Manufacturer

Problem: Delayed lead times from existing suppliers.

Solvo: Hengoseal delivered custom IDU piston seals within 18 days including tooling.

Result: 52% faster time-to-market, improved customer satisfaction.

🇺🇸 U.S. Heavy Truck Parts Distributor

Problem: Needed small-batch oil seals for aftermarket repair kits.

Solvo: Hengoseal fulfilled a 200 pcs MOQ with 120x150x15 oil seals in 7 days.

Result: Saved \$5,000/month by reducing inventory pressure.

🇮🇳 India Machinery Repair Chain

Problem: Lack of labeling and inconsistent sizes from local vendors.

Solvo: Provided complete O-Ring kit sets with accurate metric/inch conversion.

Result: Cut installation errors by 90%.

🇸🇦 Middle East Agricultural OEM

Problem: Extreme heat (over 100°C) and oil exposure.

Solvo: Customized FKM/PTFE gasket combo seals.

Result: Passed 600-hour field test, now a regular supplier.

What makes a gasket seal manufacturer reliable in 2025?

When comparing gasket suppliers, focus on the following:

✅ Speed & Delivery

- Lead times: Standard in 7–10 days, custom in 2–3 weeks

- Express: 3–5 day turnaround available

- Global delivery tracking, export docs, customs HS codes provided

✅ Cost Control & MOQ

- Factory-direct pricing, no middlemen

- MOQ as low as 100 pcs

- Volume pricing tiers available

✅ Customization & OEM Support

- In-house tooling within 7–10 days

- Branding, packaging, labels customized

- Engineering support for material and profile selection

✅ Quality Assurance

- Material testing: Shore A, tensile, aging

- Dimensional inspection via CMM

- Best storage practices ensure longevity

- RoHS/REACH compliance

How does Hengoseal handle custom gasket seal manufacturing?

Custom seals don't have to be slow or complicated. Hengoseal has streamlined the OEM process to help buyers get what they need—fast.

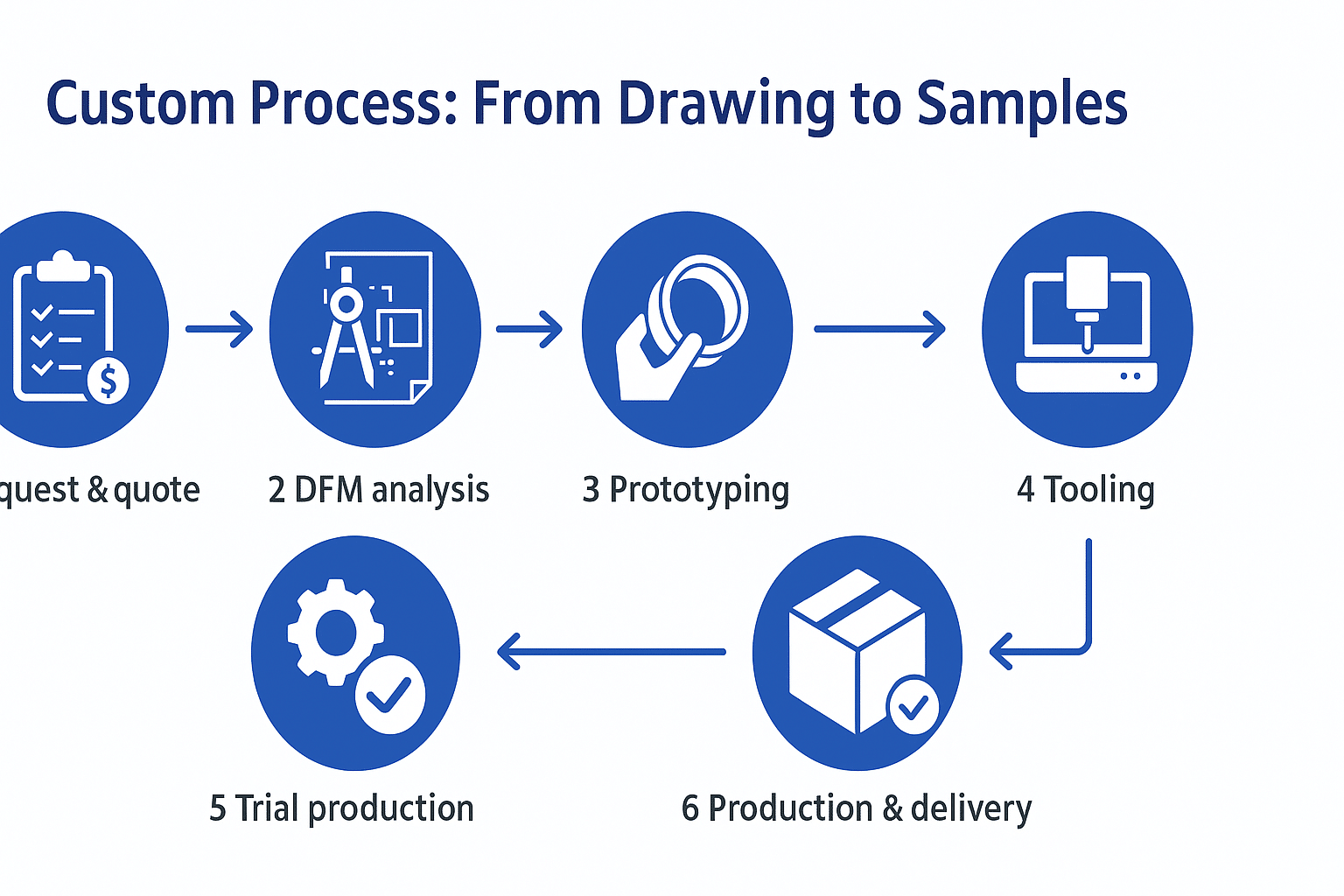

🔧 From Concept to Sample in 6 Easy Steps:

| Paŝo | Priskribo |

|---|---|

| 1. Requirement Collection | Send your drawing or sample with specs (material, size, pressure, temp) |

| 2. Technical Review | Engineering team evaluates and confirms feasibility |

| 3. Quotation | Formal quote with lead time, MOQ, and pricing tiers |

| 4. Tooling | In-house mold setup, usually 7–10 days |

| 5. Sampling | Production of test samples for functional fit |

| 6. Mass Production | Bulk manufacturing upon sample approval |

This flexible workflow supports both standard and exotic applications—from EPDM O-rings for water pumps to multi-lip rotary shaft seals used in off-road vehicles.

What gasket seal material is best for your application?

| Materialo | Plej bona Por | Tempa Gamo | Chemicals |

|---|---|---|---|

| NBR | Oil, fuel, low-temp | –40 to 120°C | Bone |

| FKM (Vitono) | Alttemperaturaj, agresemaj fluidoj | –20 to 200°C | Bonega |

| Silicono | Food-grade, low-to-mid temp | –60 to 180°C | Great |

| EPDM | Water, steam, outdoor | –50 to 150°C | Modera |

| PTFE | Chemical plants, solvents | –200 to 260°C | Superulo |

You can compare material properties in our FKM vs NBR oil seal guide for high-temperature and chemical sealing decisions.

Who is the ideal buyer for custom gasket seals?

You’re a perfect match for gasket seal manufacturing if you:

- Want lower MOQs than large MNCs

- Need mixed-size or hard-to-source seals

- Require fast shipping or frequent restocks

- Need help with seal design or material compatibility

- Are tired of inconsistent quality from trading companies

We support wholesalers, OEMs, maintenance teams, and resellers globally.

Why trust Hengoseal for gasket seal manufacturing?

Hengoseal isn't just a vendor—it’s a solution partner.

- 50+ countries served

- 500+ active OEM projects

- Full range: automotive, hydraulic, pneumatic, industrial

- Rapid sampling and prototype development

- Verified by global buyers across the US, Europe, Middle East, and Asia

If you're looking for high-quality, fast-turnaround gasket seal manufacturing, Hengoseal should be on your shortlist.

Ready to scale with better seals?

Contact Hengoseal today for faster, smarter, and more affordable sealing solutions.

📧 Retpoŝto: [email protected]

📞 WhatsApp: +86 17622979498

Related topic

Why O Ring Kits Are a Smart Investment for Industrial Buyers

How to Choose a Reliable Seal Supplier in China?

How to Select FKM Seals and O-Rings for Chemical Resistance