Choosing the right oil seal type can make or break the reliability of your machinery. Whether you're sealing a high-speed crankshaft or a dusty gearbox, the wrong seal leads to leaks, wear, and costly downtime.

Σε αυτόν τον οδηγό, θα αναλύσω το most common types of oil seals, how they’re structured, where to use them, and how to compare them based on material, application, and design.

From TC to TG4, from skeleton seals να cassette styles, let’s dive into the world of shaft sealing.

What are the main types of oil seals?

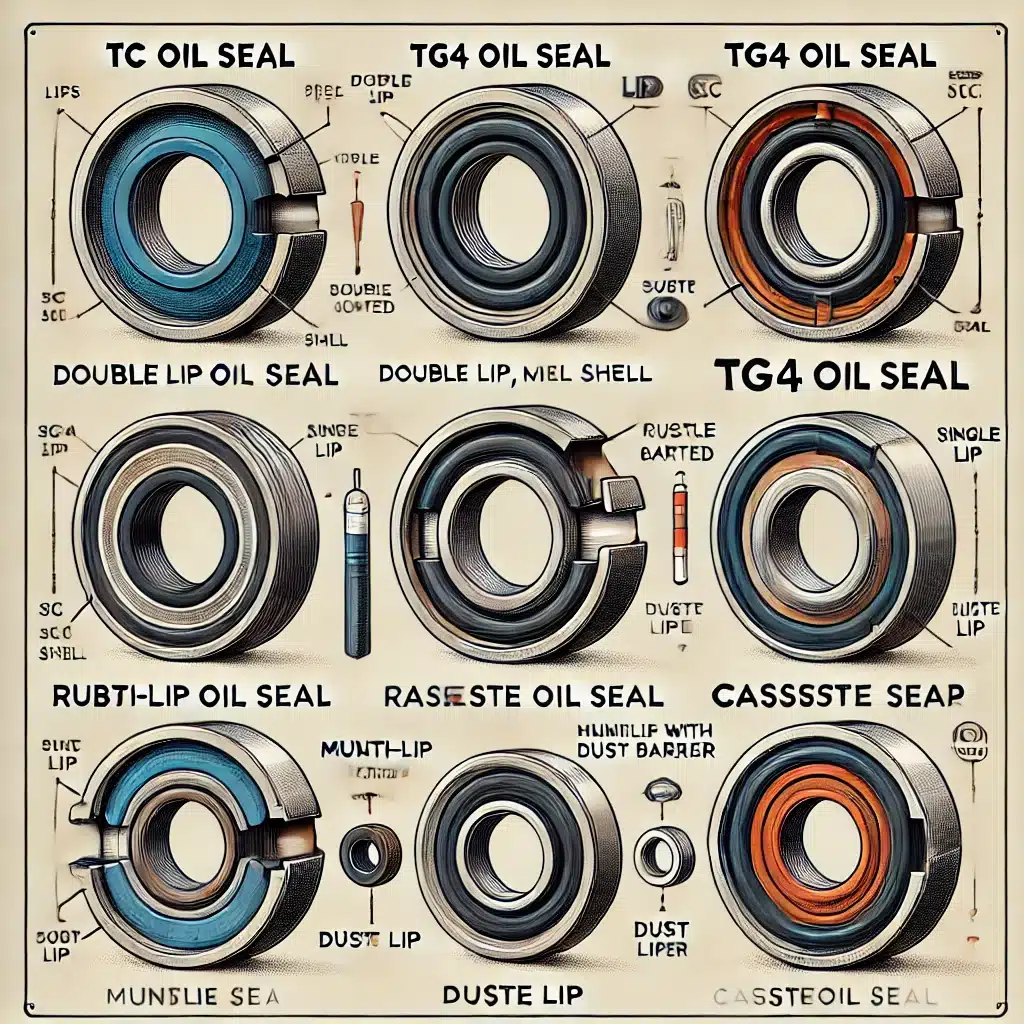

Oil seals, also known as rotary shaft seals or grease seals, come in many configurations. The most widely used types include:

| Τύπος | Δομή | Εφαρμογή |

|---|---|---|

| TC | Διπλό χείλος με μεταλλικό κέλυφος | High-speed shafts (e.g., crankshaft) |

| TG4 | Double-lip, rubber-coated shell | Dusty, vibrating systems (e.g., gearboxes) |

| SC/VC | Single-lip with metal/rubber shell | Low-speed, low-pressure environments |

| Cassette | Multi-lip with internal dust barrier | Heavy-duty mobile equipment |

| Combination Seals | Integrated sealing + dust lip | CV axles, off-road vehicles |

You can explore the detailed breakdown of the TC oil seal structure here, or dive deeper into the TG4's skeleton rubber shell advantages.

Which oil seal type is best for dusty environments?

For dusty or vibrating environments like motors in agriculture or construction, the Τσιμούχα λαδιού TG4 is a top choice.

Its rubberized outer case provides better vibration damping, and the dust lip protects internal components from dirt.

In fact, when comparing σφραγίδες λαδιού έναντι σφραγίδων σκόνης, the TG4 combines both in one solution—making it ideal for external contamination defense.

How does a TC oil seal compare to TG4?

| Χαρακτηριστικό | Σφραγίδα λαδιού TC | Σφραγίδα λαδιού TG4 |

|---|---|---|

| Shell | Full metal | Rubber-coated steel |

| Sealing Lips | Double (oil + dust) | Double (oil + dust) |

| Περίπτωση χρήσης | High-speed rotary shafts | Dusty, vibrating shafts |

| Fit Tolerance | Requires precise bore | More forgiving |

If you're unsure which to pick, our article on FKM vs NBR materials may also help you pair the right structure with the right rubber compound.

What type of oil seal is used in crankshafts?

Crankshafts typically use TC or SC type oil seals, depending on whether both lips are needed.

For front crankshaft seals, speed and heat resistance are key—so metal-shelled TC types with FKM are common.

We go into full detail in our crankshaft oil seal guide, including replacement tips and symptom diagnosis.

For rear main seal applications, especially in TOYOTA or HINO engines, check out our OEM replacement guide.

What are cassette oil seals and when should I use them?

Cassette oil seals are multi-lip, enclosed seals used in harsh, abrasive conditions like:

- Agricultural tractors

- Κατασκευαστικός εξοπλισμός

- Heavy trucks

They combine dust exclusion, oil retention, and shaft protection in a single housing. Although more expensive, they offer extended service intervals and better dirt sealing.

If you're sourcing for excavators or high-load axles, learn more in our excavator sealing guide.

Can I mix and match oil seal types based on application?

Ναί, but only if the shaft conditions match.

Για παράδειγμα:

- Replace a TC seal with TG4 only if bore and speed allow

- Don’t use SC where dust is present

- Upgrade to FKM when oil temp > 120°C

- Avoid over-engineering—match the seal to the need

Our cross-reference tools, like the Oil Seal Chart, help match OEM types to equivalent Hengoseal models.

Whether you’re replacing a crankshaft seal, selecting oil seals for your product line, or sourcing industrial-grade TG4 seals in bulk, Hengoseal offers complete solutions with low MOQ, global delivery, and OEM customization.

We support automotive, hydraulic, pneumatic and mechanical industries with proven oil sealing components—designed to perform under pressure.

📧 Email: [email protected]

📱 WhatsApp: +86 17622979498