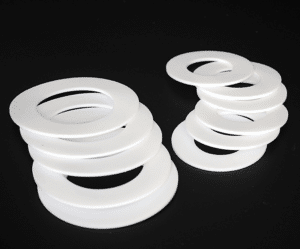

Choosing between Silicone and NBR O-rings isn’t just a technical decision—it affects system life, cost, and compliance. So, which one should you choose?

Silicone O-rings are ideal for high heat and sterile environments, while NBR O-rings dominate oil-resistant industrial applications.

Let’s compare the differences and use cases to guide your selection.

What’s the difference between Silicone and NBR O-rings?

Silicone resists heat and UV, while NBR excels with oils and fuels. Your environment determines the right fit.

| Besonderheit | Silikon O-Ring | NBR O-Ring |

|---|---|---|

| Temperaturbereich | -50 °C bis 250 °C | -40 °C bis 120 °C |

| Am besten für | Heat, food, medical | Oil, fuel, hydraulics |

| Chemische Beständigkeit | UV, ozone, dry heat | Oil, fuel, water |

| Kosten | Höher | Erschwinglicher |

Explore Silicone O-Ring specs | Learn more about NBR performance

Which O-ring material performs better in heat or oil?

- Verwenden Silikon O-Ringe for high-temperature, sterile, or outdoor conditions.

- Verwenden NBR O-Ringe in fuel, hydraulic, or lubricated environments.

| Eigentum | Silikon | NBR |

|---|---|---|

| Hitzebeständigkeit | ✅ Excellent (up to 250°C) | ❌ Moderate (up to 120°C) |

| Ölbeständigkeit | ❌ Schlecht | ✅ Ausgezeichnet |

| Wetterbeständigkeit | ✅ Ausgezeichnet | ❌ Schlecht |

How do industries apply Silicone and NBR O-rings?

Silikon O-Ringe:

- Medizinische Geräte

- Food & beverage systems

- Aerospace assemblies

NBR O-Ringe:

- Fuel injection systems

- Hydraulikzylinder

- Automotive gaskets

Compare NBR to FKM O-Rings for more oil-based solutions.

What factors should you consider before choosing?

Use this simple checklist:

-

Temperatur:

- Over 120°C → Silicone

- Under 120°C → Proceed to step 2

-

Media Exposure:

- Oil/fuel → NBR

- UV, dry heat, ozone → Silicone

-

Cost Sensitivity:

- Budget-critical → NBR

- Long-term performance → Silicone

Need custom specs? Try our O-Ring-Maker-Werkzeug.

What do customers say about these materials?

- “NBR O-Rings sealed our diesel pumps perfectly.” – Automotive client

- “Silicone survived 200°C sterilization cycles with no cracks.” – Medical OEM

Tipp: Verwenden this guide to understand sealing fundamentals.

Abschluss

Silicone and NBR serve different needs—match material to environment and you’ll seal with confidence.

Choose the right O-ring for your system

📩 E-Mail: [email protected]

📞 WhatsApp: +86 17622979498

Related post