I’ve seen factories lose thousands to hydraulic leaks. The right seal isn’t just a part — it’s a productivity guarantee.

Hydraulic seals prevent fluid leaks, reduce friction, and maintain pressure, ensuring industrial machines run efficiently under extreme conditions.

Curious which hydraulic seal suits your application best? Here’s everything you need to know.

What Are Hydraulic Seals and Why Are They Essential?

Hydraulic seals are elastomeric components that contain hydraulic fluid and maintain pressure within cylinders and pumps.

They form a tight barrier between moving and stationary parts, preventing leaks even in high-pressure environments.

Want to understand how O-rings contribute to sealing efficiency? Check our O-ringens grundlæggende guide.

Which Hydraulic Seal Type Is Best for Industrial Applications?

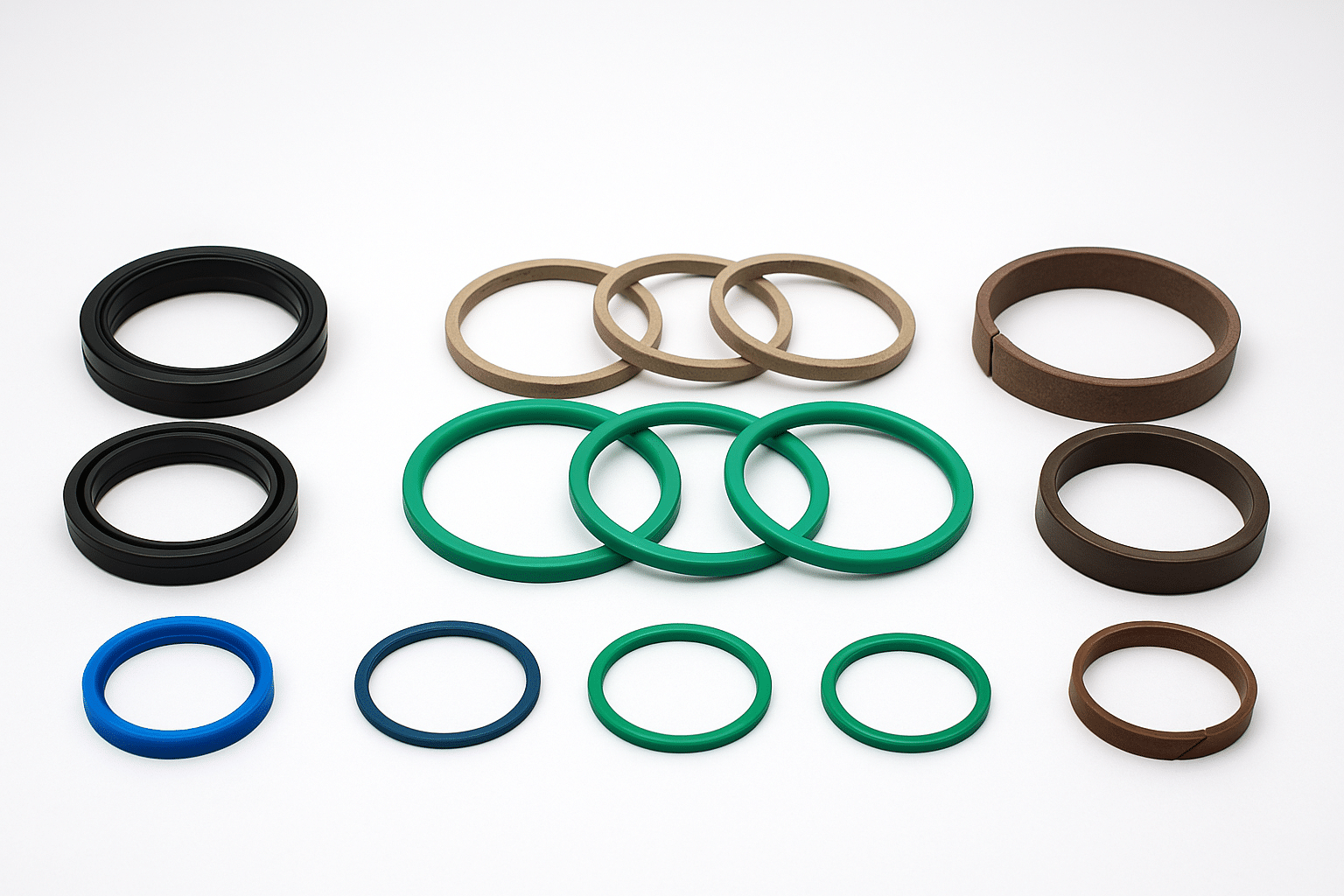

Choosing between rod seals, piston seals, and wiper seals depends on motion and contamination exposure.

| Tætningstype | Fungere | Bedste brug |

|---|---|---|

| Stangforsegling | Prevents fluid leakage in cylinder rods | Industrielle hydrauliske cylindre |

| Stempeltætning | Maintains pressure within cylinder bores | Press machines, loaders |

| Viskerforsegling | Blocks dust and debris from entering | Construction and outdoor equipment |

For a detailed selection guide, explore our Hydraulic Seals Guide.

How to Select the Right Hydraulic Seal Material?

Material choice impacts performance, lifespan, and compatibility with fluids and temperatures.

| Materiale | Nøglestyrker | Bedste brug |

|---|---|---|

| TPU | Høj slidstyrke, fleksibilitet | Heavy-duty industrial systems |

| NBR | Fremragende oliebestandighed | Hydraulic pumps, general use |

| FKM | High-temperature & chemical resistance | Aerospace, high-heat environments |

For customized solutions, check our O-ringe maker service.

Can Hydraulic Seals Handle High-Pressure Industrial Systems?

Absolutely. High-performance seals like TPU rod and piston seals withstand intense pressure without sacrificing efficiency.

A client using press machines faced frequent leaks. Upgrading to TPU seals resulted in:

- ✅ 65% fewer seal failures

- ✅ 40% longer machine uptime

- ✅ 30% reduction in maintenance costs

For extreme applications, I recommend pairing FKM og PTFE seals for maximum durability.

How to Prevent Common Hydraulic Seal Failures?

Failures often stem from:

- Bruger det forkerte materiale

- Shaft misalignment

- Overkomprimering

- Utilstrækkelig smøring

For practical prevention tips, refer to our Seal Failure Guide.

Where to Source High-Quality Hydraulic Seals in 2025?

Hengoseal offers:

- OEM-grade hydraulic seals

- Custom sizing and materials

- Fast international shipping

Explore our top products:

- FKM O-ringe til højtemperaturforsegling

- Nitrile O-Rings for General Hydraulics

- Hydrauliske tætningssæt efter størrelse

📩 [email protected]

📞 WhatsApp: +86 17622979498

Konklusion

The right hydraulic seal boosts reliability, cuts downtime, and ensures efficient operations. Match seal type and material to your specific application for best results.

Upgrade Your Hydraulic Systems with Hengoseal’s Premium Seals

📩 E-mail: [email protected]

📞 WhatsApp: +86 17622979498

Related topic

Types of Oil Seals: Pros, Applications & Comparison Guide

Best Hydraulic Seal Manufacturers: Global Comparison

How Hengoseal Helped Reduce Oil Leaks by 30%