Choosing the wrong seal type can lead to performance failures and higher maintenance costs. I’ve seen systems shut down simply because a hydraulic seal was used where a pneumatic one was needed—or vice versa.

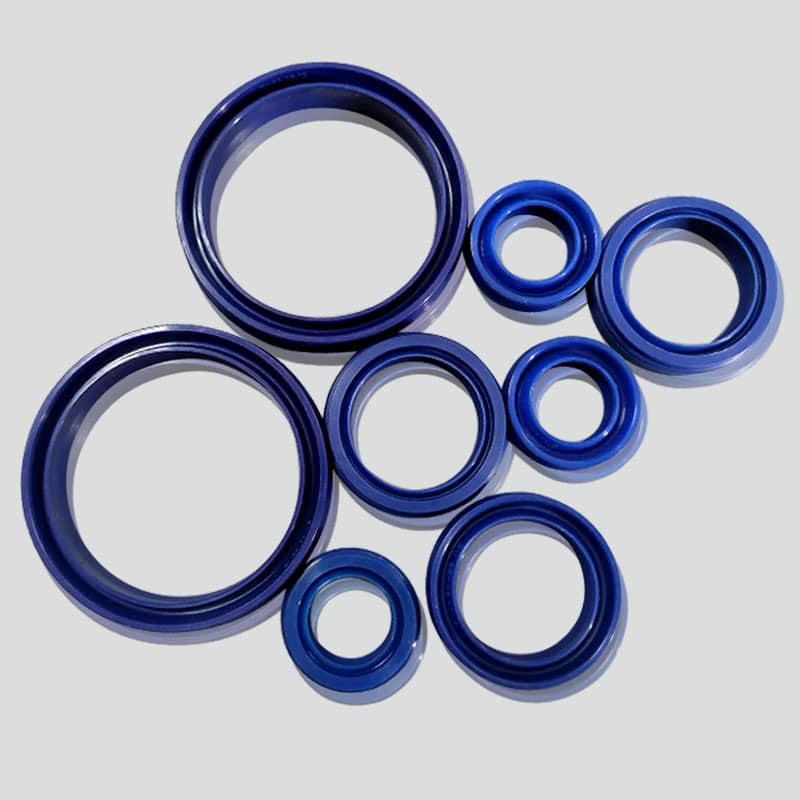

Hydraulic seals are built for high-pressure fluid systems, while pneumatic seals are ideal for low-pressure air systems. This article helps you choose the right one based on pressure, material, and application.

What is the difference between hydraulic and pneumatic seals?

While both prevent leaks and contain pressure, they’re designed for different types of systems.

| ميزة | الأختام الهيدروليكية | الأختام الهوائية |

|---|---|---|

| وسط التشغيل | Liquid (Oil, Water) | الهواء المضغوط أو الغاز |

| التعامل مع الضغط | Up to 10,000 PSI | Up to 250 PSI |

| تكوين المواد | PTFE, FKM, NBR, TPU | TPU, NBR, Silicone |

| مدى درجة الحرارة | من -40 درجة مئوية إلى 200 درجة مئوية | -30 درجة مئوية إلى 100 درجة مئوية |

| التطبيقات | Heavy equipment, الهيدروليكا الصناعية | الروبوتات, automation, packaging |

What are the ideal applications for hydraulic seals?

Hydraulic seals are best suited for environments with extreme pressure and heat.

They are used in:

- Mining and excavation equipment

- Press machines and lifts

- Oilfield and marine hydraulics

We often recommend UN hydraulic rod seals و KDAS buffer seals for high-pressure cylinders in industrial settings.

What are the benefits of pneumatic seals in automation?

Pneumatic seals thrive in systems where speed and cleanliness matter more than pressure.

وهي مثالية لـ:

- Assembly line actuators

- Medical and pharmaceutical tools

- Food and electronics packaging lines

In these environments, we’ve seen great results with TPU-based pneumatic cylinder seals و buffer rings for shock absorption.

How do you extend seal lifespan in both systems?

Proper maintenance can double seal lifespan.

Tips:

- Inspect seals monthly for cracking or swelling

- Use correct lubricants and operating pressure

- Keep systems free of dust or fluid contamination

- Choose the right kit from the start—like our standard & custom hydraulic seal kits

خاتمة

Hydraulic for power and pressure, pneumatic for precision and speed. Each seal type has a role—choose wisely for maximum efficiency.

Let’s help you match the right seal to your system

📩 Email:[email protected]

📞 WhatsApp:+86 17622979498

Related topic

How to Choose and Replace Hydraulic Seals

High-Performance Pneumatic Seal Guide

How to Extend the Lifespan of Pneumatic Seals