Standard seals don’t always fit. Whether it’s due to unique groove sizes, uncommon materials, or OEM requirements—custom hydraulic seals are often the only way to keep your system running.

Custom hydraulic seals are tailored to match exact dimensions, materials, and operating conditions for cylinders, pumps, and industrial machines. With our factory-direct service and low MOQ, custom doesn’t mean expensive.

Let’s explore how to create the perfect seal for your system—step by step.

What is a custom hydraulic seal?

A custom seal is manufactured to meet non-standard groove sizes, pressure ratings, temperature ranges, or application-specific demands.

Unlike off-the-shelf seals, custom options:

- Match legacy or imported equipment

- Solve recurring seal failures

- Combine multiple functions into one profile

- Use specialized materials like PTFE, FKM, or FDA-grade rubber

If you’re unsure where to start, we can help match your seal with OEM specs or reference it against our oil seal cross-reference chart.

When do you need a custom hydraulic seal?

Custom seals are essential when:

- You can’t find a standard size

- The seal groove has been worn or re-machined

- Your system uses uncommon fluids (e.g., bio-oils, glycol)

- You need a hybrid design (seal + guide + buffer in one)

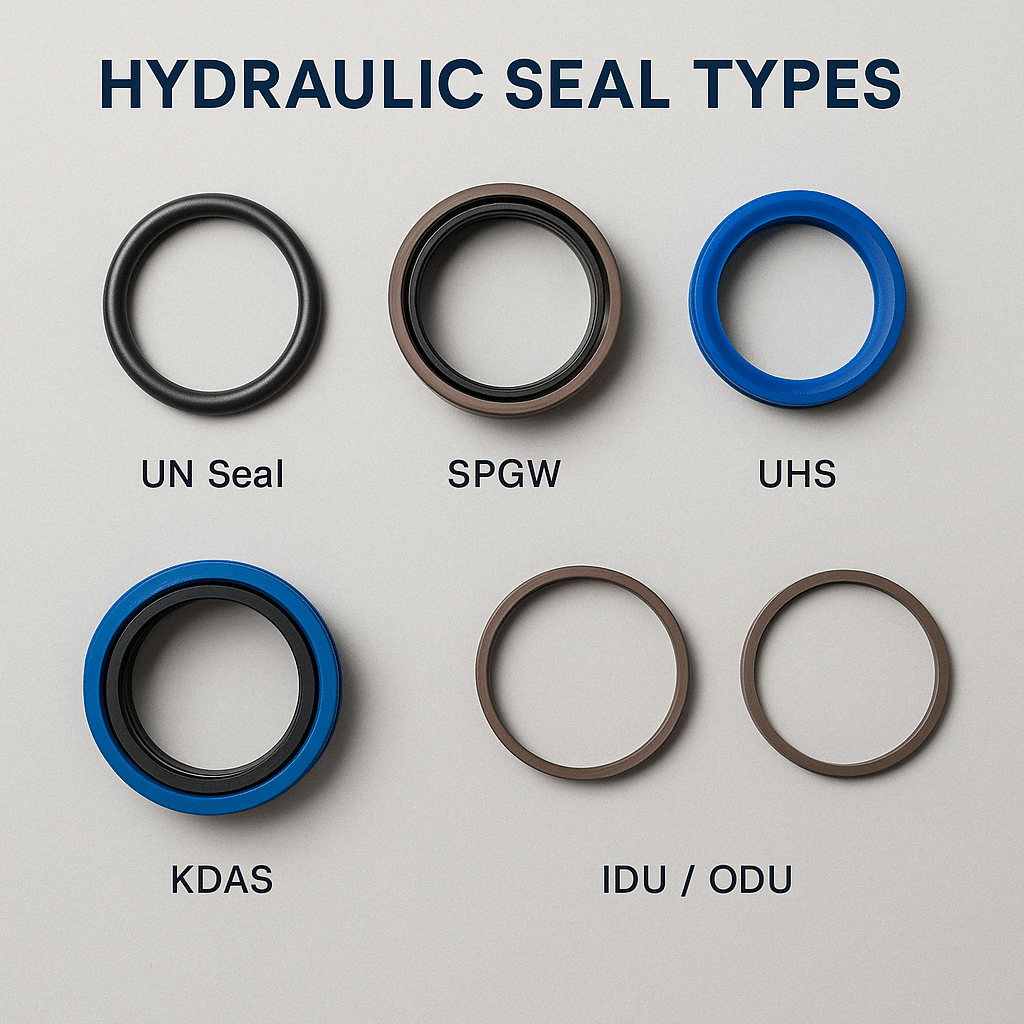

In these cases, choosing a pre-molded KDAS or V-type seal won’t be enough. Instead, we design to fit your exact cylinder drawing or sample.

How do you design a custom seal?

We follow a 3-step process:

-

Send us your specs

- Dimensions (ID, OD, groove width/depth)

- Working pressure, fluid type, stroke speed

- Preferred material or temperature range

-

Confirm the drawing

We’ll generate a 2D drawing or confirm against OEM references. -

Prototype and ship

For small MOQ (even 10 pcs), we provide CNC or molded production with rapid delivery.

Need help measuring your old seal? Refer to our guide on how to measure hydraulic seals accurately.

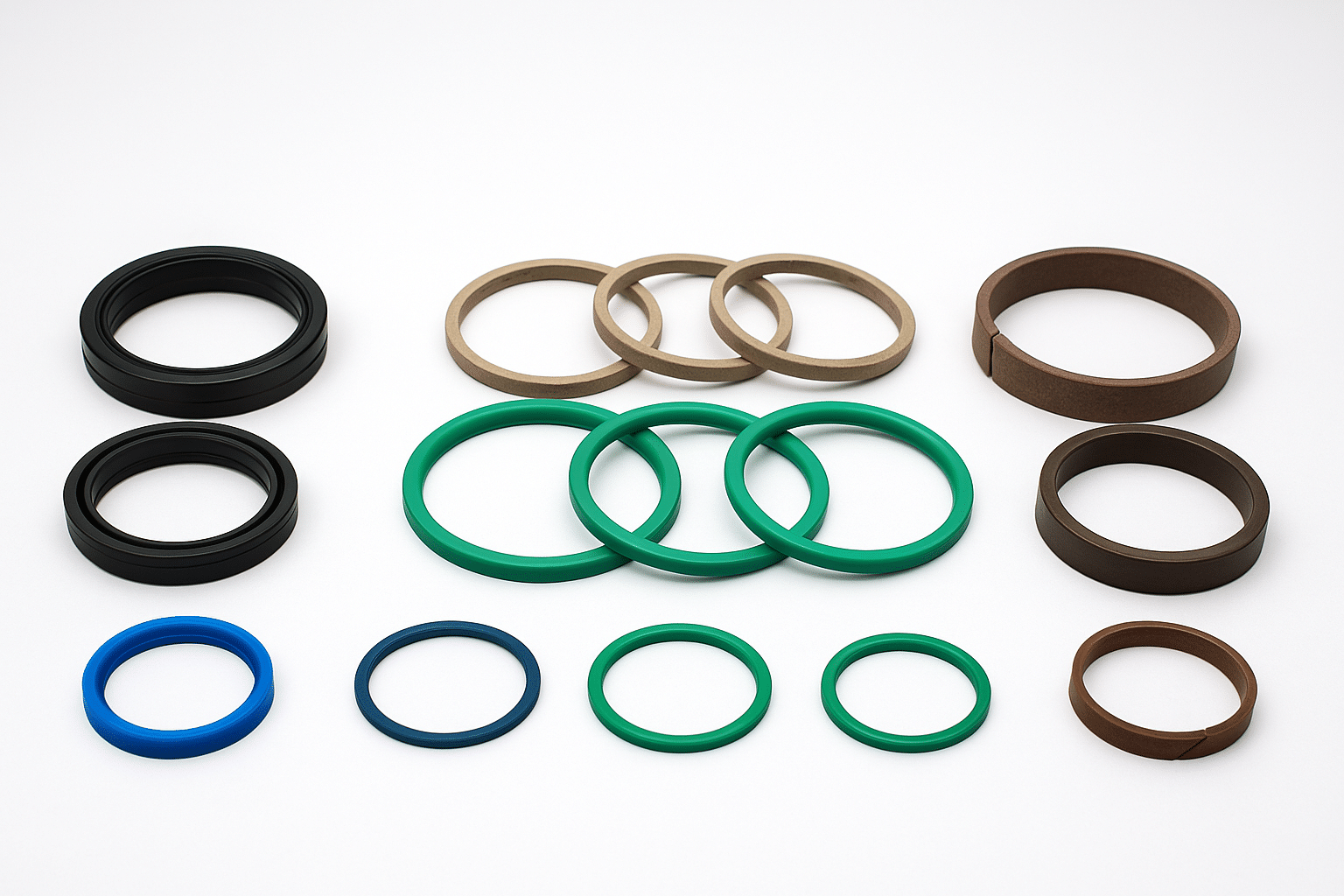

Which materials can be customized?

We offer multiple materials for different conditions:

| مادة | سمات | الأفضل لـ |

|---|---|---|

| ن بي آر | مقاومة الزيت، منخفضة التكلفة | Standard hydraulics |

| فكم | High-temp, chemical resistance | Chemical + mining |

| بولي يوريثين | Abrasion resistance | Construction + forklifts |

| مادة البولي تترافلورو إيثيلين | Low friction, extreme temp | Pumps, cylinders, valves |

| سيليكون | Food-grade, soft | FDA or water contact systems |

For high-pressure systems, combine a PTFE sealing ring with a PU energizer and a KDAS buffer seal for shock absorption.

What’s the MOQ and lead time for custom seals?

We specialize in low-MOQ custom production, including:

- MOQ from 10 pcs

- Lead time as fast as 3–5 days for CNC cut seals

- Molded samples in 7–10 days

- Mixed-size kits available for maintenance teams

Unlike large brands, we don’t require huge minimums. Even if you only need a few sizes, we’re happy to help. Check our custom rubber solutions page for full options.

What industries benefit from custom sealing?

Custom hydraulic seals are used in:

- Agriculture (tractors, plows, sprayers)

- Mining & steel (cylinders, presses)

- Construction (excavators, lifts)

- Food & beverage (FDA-grade seals)

- Injection molding and hydraulic presses

We’ve helped clients match discontinued OEM seals, improve leak rates, and extend service life with UN rod seal + custom buffer combos.

خاتمة

Custom hydraulic seals are no longer slow or expensive. With the right specs, materials, and partner—you can build the perfect seal for any system.

Start your custom seal project now

📩 mail:[email protected]

📞 WhatsApp:+86 17622979498

Related topic

- UN Hydraulic Seal: OEM Rod Sealing Guide

- V-Type Hydraulic Seals for Extreme Pressure

- How to Measure Hydraulic Seals

- KDAS Compact Seal for High-Pressure Buffers