Round o rings are everywhere—but sometimes, they’re not enough. In certain industrial applications, a round profile just doesn’t create the seal you need. That’s where a square o ring kit becomes essential.

Square profile o rings provide better sealing performance in static, high-pressure, or high-vibration environments. Let’s explore when, why, and how to use them—and what to look for in a reliable square o ring assortment kit.

What is a square o ring?

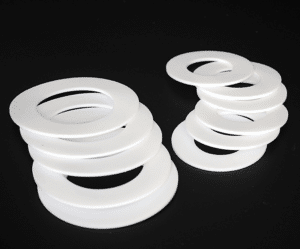

A square o ring is a sealing ring with a square cross-section instead of a round one.

Also called square-cut o rings or quad rings, they sit flush against flat surfaces and distribute compression force more evenly. This makes them ideal for flanged joints, static grooves, and non-rotational sealing environments.

When should I use a square o ring instead of a round one?

Use square o rings when you need better sealing in flat, high-pressure, or non-moving joints.

They’re preferred in situations like:

- Hydraulic cylinder end caps

- High-load face seals

- Valves or flanged pipe fittings

- Vacuum sealing

Round o rings may roll or deform under high pressure. Square o rings stay in place and seal more securely.

👉 Learn more in our O Ring Kit Comparison Guide.

Are square o rings better for high-pressure seals?

Yes. Square o rings resist rolling and extrusion better than round o rings, especially under high PSI loads.

Their shape provides more contact area and prevents distortion in applications involving:

- Hydraulic press systems

- Static groove designs

- Cylinder end seals

For high heat + pressure combined, consider our High Temperature Viton O Ring Kit.

What materials are square o rings made of?

Like standard o rings, square o rings can be made from NBR, Viton, EPDM, PTFE, and Silicone.

| Material | Temp Range | Chemical Resistance | Best Use |

|---|---|---|---|

| NBR (Buna-N) | -40°C to 120°C | Good (oils, fuels) | Hydraulic, automotive |

| Viton (FKM) | -20°C to 200°C | Excellent (fuel, chemicals, heat) | High-temp & chemical systems |

| PTFE | -200°C to 260°C | Excellent | Static, aggressive chemicals |

| Silicone | -60°C to 200°C | Fair | Food, pharma, light pressure |

At Hengoseal, we provide square o ring kits in NBR and Viton as standard, with custom material options available on request.

What’s included in a square o ring kit?

Our kits come with 30+ sizes of square-section seals to fit standard SAE or ISO grooves.

| Kit Type | Standard | Sizes | Material Options | Ideal For |

|---|---|---|---|---|

| Square O Ring Kit | SAE / ISO | 30+ | NBR / Viton | Static sealing, hydraulic, valves |

| OEM Kits | Custom | As required | NBR / Viton / PTFE | Industrial distributors, brands |

Each kit is packed in a labeled plastic box with compartments and a printed size chart. OEM branding is available for bulk orders.

Can I use square o rings for dynamic applications?

Usually not. Square o rings are best for static seals—not recommended for rotary or reciprocating motion.

If you're sealing a piston or shaft, use standard o rings or specialized X-rings. But for static compression under pressure, square rings are often more durable.

How to choose the right size square o ring?

Measure the groove dimensions:

- Inner Diameter (ID)

- Groove Width / Depth

- Compression range

Or simply use our standard kit that covers the most common sizes in field repair and maintenance. For non-standard dimensions, we offer custom molded square rings with low MOQ.

Final Thoughts on Square O Ring Kits

Square o rings aren't a gimmick—they solve specific sealing problems that round rings can't. If you’re working with flat or high-pressure static interfaces, adding a square o ring kit to your toolbox makes all the difference.

Get a Quote for Square O Ring Kits

Need square profile o rings in NBR or Viton for your repair team or distribution business?

📩 Email: [email protected]

📱 WhatsApp: +86 17622979498

We support OEM, low MOQ, and fast delivery worldwide.