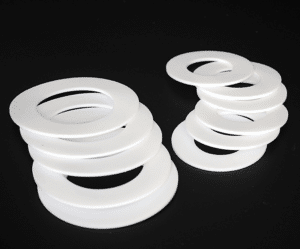

Need sealing performance across high heat or aggressive chemicals? Choosing between Silicone O-Rings and FKM O-Rings can define your system’s reliability.

FKM O-rings excel in chemical and oil resistance, while Silicone O-rings are best in extreme heat and cold.

Here’s how I compare them and choose the right fit every time.

What is the difference between Silicone and FKM O-Rings?

Silicone is flexible and food-safe; FKM is robust and chemical-resistant.

| Property | Silicone O-Ring | FKM O-Ring |

|---|---|---|

| Temperature Range | -50°C to 250°C | -20°C to 200°C |

| Chemical Resistance | UV, ozone, limited fluids | Fuels, oils, solvents |

| Application | Food, medical, low-stress | Fuel, automotive, dynamic |

| Cost | Lower | Higher |

Silicone O-Rings Details | Explore FKM Options

Which O-Ring performs better under temperature extremes?

If you’re sealing in extreme cold or static high heat, go for silicone. For high-temp chemicals, choose FKM.

| Material | Lowest Temp | Highest Temp (Typical) |

|---|---|---|

| Silicone | -50°C | 250°C (300°C additives) |

| FKM | -20°C | 200°C (up to 300°C) |

FKM for high-heat chemical sealing

When should I use Silicone or FKM O-Rings?

Use Silicone O-Rings in:

- Food-grade or sterile systems

- Cold storage

- Low-pressure static sealing

Use FKM O-Rings in:

- Automotive fuel lines

- Hydraulic systems

- Oil, chemical, and acid environments

Compare EPDM vs FKM for chemical sealing

Which O-Ring lasts longer and offers better ROI?

| Metric | Silicone O-Rings | FKM O-Rings |

|---|---|---|

| Cost | Lower upfront | Higher upfront |

| Lifespan | Moderate | Long-lasting |

| Maintenance Cycle | Frequent | Minimal |

Silicone is great for short-term or clean use. FKM pays off in aggressive systems.

What do users say about Silicone vs FKM O-Rings?

- “Silicone was perfect for our autoclave seals.” – Food OEM

- “FKM cut our chemical leakage incidents by half.” – Oil refinery manager

Use our O-Ring Maker Tool for custom needs.

How do I choose between Silicone and FKM O-Rings?

Follow this decision path:

- Exposure to oil/fuel? → Use FKM

- High heat, no fluids? → Use Silicone

- Dynamic movement? → Use FKM

- FDA-grade or static? → Use Silicone

📞 Still unsure? Contact us at [email protected]

Conclusion

Choose Silicone O-Rings for heat, cold, or food-grade sealing. Use FKM when oil, fuel, or chemicals are involved.

Request custom O-Rings today

📩 Email: [email protected]

📞 WhatsApp: +86 17622979498

Related post