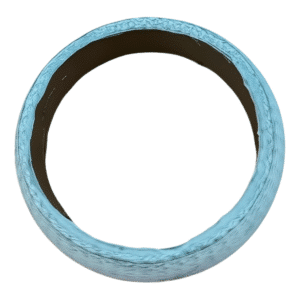

Coupling Component

- 0 MOQ

- 3 DAYS DELIVERY

- 100% customer repurchase rate

Send your inquiry now !

分类 GASKET

Coupling Component

Coupling components—sometimes referred to as coupling elements or rubber couplings—are essential for connecting rotating shafts, absorbing shocks, and compensating for slight misalignments. By ensuring smooth torque transmission and reducing vibration, these elements play a pivotal role in preserving equipment longevity and optimizing system performance. At Hengoseal.com, we offer a versatile range of rubber and polymer-based coupling solutions designed for various mechanical, hydraulic, and pneumatic applications.

@buyer Leer más

I've been working with Hengoseal for over three years, and it's been a great experience throughout. Their product quality is consistently reliable, the pricing is reasonable, and they always deliver on time. Even when I have smaller orders, they’re very supportive — which I truly appreciate.

Product Details

- NL Tooth Set (Nylon)

Molded gear sleeves designed to fit precisely, delivering stable engagement and minimal backlash in light to moderate load conditions. - NM Elastic Pad (NR)

Manufactured from natural rubber (NR) for excellent damping properties; helps reduce noise and vibration in rotating machinery. - L Type (NBR/TPU)

A classic design for torque transfer, providing resilient connection and moderate resistance to oils and wear. - HRC (NBR/TPU)

Combines a split design with shock absorption, facilitating easy installation and alignment in diverse industrial settings. - MH/CC (NBR/TPU)

Offers versatile coupling options suitable for standard motor-shaft connections, balancing flexibility with robust sealing properties. - BWN (TPU)

A tough, abrasion-resistant option ideal for high-speed machinery, thanks to thermoplastic polyurethane’s durability. - GR (TPU/NBR)

Features enhanced elasticity and chemical resistance, ensuring reliable performance under variable loads and environments. - H Type (NBR/TPU)

Focused on reducing torsional vibration, perfect for shaft-to-shaft connections in equipment requiring steady torque transfer. - MT (NBR/TPU/FKM)

Handles higher temperature or chemical exposure, thanks to the optional FKM layer combined with NBR/TPU base materials. - T Type (TPU/NR/PVC/FKM)

Provides multiple material combinations to suit specific temperature ranges, chemical exposures, and torque requirements. - Elastic Pad (TPU/NR/PVC/FKM)

A flexible insert designed for various coupling setups, minimizing misalignment stress and extending system life. - Elastic Column (TPU/NR/PVC)

Cylindrical elements that offer shock absorption and dampening in mechanical transmissions. - YOX (TPU/NR)

Suited for medium-duty applications, combining two materials that handle repetitive stress effectively. - Quad Ring (TPU/NR/PVC)

A unique shape that delivers uniform contact, reducing wear and ensuring consistent coupling performance. - Rubber Twelve Angle (NBR)

A multi-sided insert providing strong load distribution, ideal for applications that require enhanced grip and vibration control.

Material Advantages

- Nylon: Lightweight, high strength, suitable for moderate torque.

- NR (Natural Rubber): Excellent elasticity and shock absorption.

- NBR (Buna-N): Good oil and wear resistance for industrial environments.

- TPU (Thermoplastic Polyurethane): Outstanding abrasion resistance and flexibility.

- FKM (Viton®): Exceptional chemical and heat resistance for demanding conditions.

- PVC: Economic polymer with moderate chemical and weather resistance.

Selecting the right blend ensures each coupling component performs reliably under its intended load, speed, and environmental conditions.

Typical Applications

- Mechanical Transmissions: Prevent misalignment damage and reduce torsional vibrations.

- Hydraulic Systems: Provide stable shaft connections under varying pressure and fluid conditions.

- Pneumatic Equipment: Absorb shocks and safeguard components operating at high cyclic speeds.

- Industrial Machinery: Prolong machinery life by mitigating vibration-induced wear.