Some environments are just too harsh for standard rubber. If you’re working with acids, fuels, solvents, or superheated steam, you need more than a basic o ring.

You need a PTFE o ring kit—built for extreme resistance, uncompromising sealing, and industry-grade durability.

Let’s look at when, where, and why you should use PTFE o rings—and how they compare to traditional rubber materials.

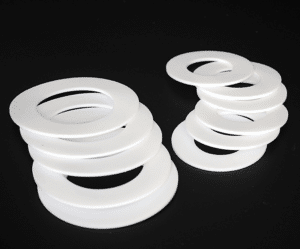

What is a PTFE o ring kit?

A PTFE o ring kit includes multiple sizes of o rings made from polytetrafluoroethylene—a chemically inert, non-elastic, and high-temperature-resistant polymer.

Also known as Teflon o rings, PTFE o rings are widely used in:

- Chemical processing

- Food and pharmaceutical manufacturing

- High-temperature steam systems

- Aerospace and laboratory seals

Unlike NBR or Viton, PTFE doesn’t degrade when exposed to aggressive chemicals or extreme heat.

When should I use PTFE instead of rubber o rings?

Use PTFE when:

- Operating temperatures exceed 200°C

- Sealing against aggressive media: acids, alkalis, fuels

- You need low friction and zero contamination

- Compression set or chemical attack is an issue

If you’re not sure whether rubber is enough, read this comparison:

Rubber O Ring Kit vs PTFE: Which Material is Right?

How does PTFE compare to Viton and NBR?

| Property | PTFE | Viton (FKM) | NBR (Buna-N) |

|---|---|---|---|

| Max Temp | 260°C | 200°C | 120°C |

| Chemical Resistance | ★★★★★ | ★★★★☆ | ★★☆☆☆ |

| Flexibility | Rigid | Medium | Flexible |

| Compression Set | Very Low | Low | Medium |

| Food Contact Safe | Yes | No | No |

PTFE is ideal when nothing else survives—but it’s less flexible and harder to install.

For high-temperature flexibility, try our

Viton O Ring Kit.

Are PTFE o rings reusable?

Yes—PTFE o rings are chemically stable and have a long service life.

But be cautious:

- Do not reuse if distorted or scratched

- Always inspect the groove for sharp edges

- Avoid using in dynamic seals unless specifically designed

PTFE performs best in static or low-motion sealing.

What’s included in a PTFE o ring kit?

Our PTFE kits include up to 30 common sizes in either metric or inch standards.

| Kit Type | Sizes | ID Range | Cross Section | Packaging |

|---|---|---|---|---|

| 200 PCS (PTFE) | 20–30 | 3mm – 48mm | 1.5–3.5mm | Plastic case with label |

| OEM Options | Custom | Any | Any | Custom branded |

We can mix PTFE and rubber o rings in one kit for distributors and repair teams.

→ View Our Assorted O Ring Kits

Is PTFE food-grade and FDA approved?

Yes. Virgin PTFE is:

- FDA 21 CFR 177.1550 compliant

- Chemically inert

- Non-stick and non-contaminating

- Safe for CIP and SIP processes in food, pharma, biotech

We offer food-grade kits on request for equipment manufacturers.

What are PTFE o rings best used for?

Top use cases:

- Chemical tanks and valves

- Steam sterilization systems

- Instrumentation and gauges

- Aerospace components

- UV or radiation-exposed systems

- Food and beverage piping

Final Thoughts on PTFE O Ring Kits

PTFE o rings are not a rubber substitute—they’re an upgrade.

If your system deals with chemicals, pressure, heat, or contamination risk, a PTFE o ring kit gives you peace of mind and performance others can’t.

Get Your Custom PTFE O Ring Kit Today

Need FDA-grade, high-temp, or chemical-proof o ring kits?

📩 Email: [email protected]

📱 WhatsApp: +86 17622979498

We ship OEM, private label, and small-batch PTFE kits worldwide.